VERBUND is the largest electricity provider of Austria and generates over 92 percent from hydro power. To accelerate the energy transition, VERBUND wants to invest 15 billion euros by 2030 that will allow a generation of up to an additional 8 TWh of green electricity. To support this energy transition, VERBUND has decided to diversify their portfolio and aggressively add more solar PV plants to their generation mix.

As a part of the VERBUND X Acceleration program, they selected SmartHelio among 300+ applicants to exclusively work on predictive analytics for their solar assets. SmartHelio, a Switzerland & California based clean-tech company, specializes in advanced data analytics solution to prevent downtime in solar PV assets and make them more resilient. The aim of this collaboration was to utilize SmartHelio’s agility and speed to build a strong foundation of solar asset management at VERBUND.

What problem did VERBUND want to solve?

The digital infrastructure established at VERBUND to monitor the performance of these assets only helps the asset management team in reactive maintenance which, for the most part, mandates a physical inspection of the site to zero down on the root causes of underperformance.

The VERBUND team had 3 major limitations with their existing infrastructure: lack of predictive analytics, especially in cases of equipment failure, alerts are received for major faults after faults have already occurred and undetected reasons for underperformance.

Only a 1% underperformance would lead to ~ EUR 1200 per MW per year of loss. This means that by 2030, a 1% underperformance of their portfolio will amount to EUR 2.4 million of annual losses. Given this scale of losses due to the reactive nature of O&M currently, VERBUND already started preparing a digital twin model so that they can quickly identify underperforming sections of the plant. But since VERBUND’s team has decades of experience in hydro and wind power plants and they very well understood that automated prediction of faults and root cause analysis, on top of a robust digital twin model, will be a key to ensuring the sustainability and profitability of their solar PV assets.

Having an advanced predictive analytics solution as a part of their digital infrastructure will make their internal asset management team very efficient and it will also help any third-party O&M service provider to proactively maintain these assets for VERBUND.

How SmartHelio was poised to solve VERBUND’s needs?

SmartHelio has built software with Physics-informed AI based algorithms which can detect the early signature of faults occurring in solar PV plants. Using SmartHelio’s software, solar developers have reported upto 5% increase in their revenues and 80% reduction in time taken during O&M activities from underperformance detection to fixing the fault.

SmartHelio gives two offers: access to their software (via SaaS) or integration of their algorithms into any existing digital infrastructure or central monitoring solution. It was this latter option which attracted VERBUND the most. VERBUND wants to empower their asset management team by having flexibility to utilize their field experience to further improve a predictive analytics solution and that’s where their needs perfectly aligned with SmartHelio’s vision for their clients: transparency and empowerment!

The intelligent insights produced by SmartHelio’s analytics, helps the stakeholders in the entire value chain of solar development. An overview of the benefits are as follows:

Bidding: Location specific long-term production forecasting

Pre-construction: Selection of equipment and system design for project’s longevity

Post-construction: Automated asset management

Keeping focus on the post-construction benefits, SmartHelio was poised to demonstrate how VERBUND can utilize predictive analytics to bring about fundamental changes in their current asset management practices and make their solar assets more profitable through its life.

“Overall it was a lot of hard work, long hours but we ended each day socializing with one another which was very refreshing”. – Shankaransh Srivastava, SmartHelio VP of Marketing & Customer Success.

What challenges were faced during the implementation?

Good quality, standardised data are the obvious basic requirements for data analytics. As both teams began to collect the meta and time-series data for the two plants, the following misalignments were found:

Both plants had different data formats

Timestamp granularity were different

Data issues stemming from data logger malfunction

Granularity of data collection were different

Immediately, both teams met to discuss the solution to this, and within 48 hours data customisation scripts were built by SmartHelio for both plants for seamless integration of this data with our software. For accurate benchmarking, both teams worked on the mapping between time-series data and meta data is. All other data issues were handled automatically by SmartHelio’s data sanitation algorithms.

What was the outcome of this collaboration?

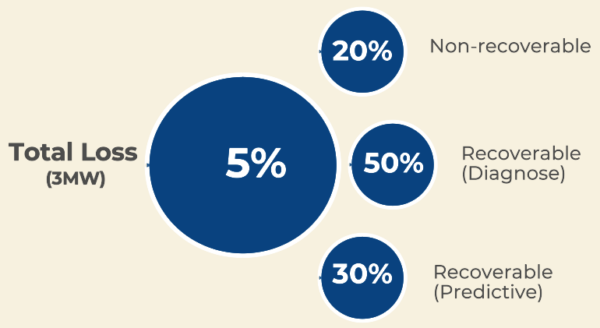

The two plants selected for this project were installed in Austria. The 1.7MW plant was installed on a tracker-based system while the 1.33MW plant was a fixed tilt ground mounted solar PV system. Last one year of data, where VERBUND already knew the major faults which have occurred, was simulated in real-time within SmartHelio’s software. An average of 5% underproduction was detected in this portfolio out of which 80% of the faults could be recovered. Not only were those major faults detected (previously known to VERBUND’s team), but even unknown losses were classified.

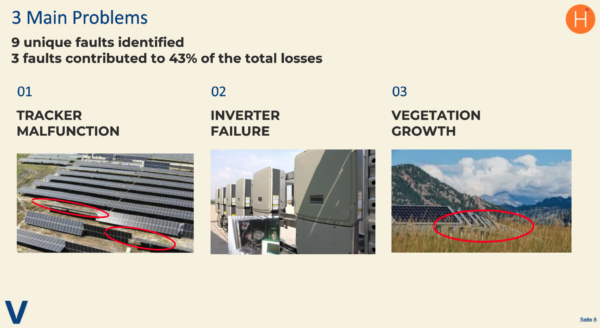

Collectively there were 9 major types of faults identified (disconnected string, PV module damage, ground fault, vegetation growth, tracker malfunction, inverter failure, MPPT malfunction, shading and soiling) and 3 of these contributed to 43% of the losses. In 2022, these 3 issues were either identified after they had occurred or after a physical inspection of the site. During this project, however, SmartHelio’s software was able to detect the first day when the early signature of these faults was detected in the plant, and prior to any underperformance losses were event generated.

So, only with predictive analytics, 30% of the total losses could have been avoided. Based on these two solar plants, it was also evaluated that ~EUR 4000 per MW per year could be saved from the lost revenue if SmartHelio’s software is deployed on VERBUND’s assets. The successful demonstration of predictive analytics and detecting the unknown reasons for underperformance sufficed VERBUND’s requirements in validating the authenticity of SmartHelio’s software.

The capability of Smarthelio’s software to detect the early signatures/patterns of faults, being able to predict the failure and project the associated losses could be used by VERBUND to optimize their O&M activities and take pro-active actions before losses start hurting the performance of the plant substantially. SmartHelio works cross functionally with Asset Management, O&M, Engineering and site teams to ensure that their software is utilised most efficiently by all stakeholders.

Conclusion

The results from this project confirmed the alignment of VERBUND’s asset management vision and SmartHelio’s offering. On top of the technical alignment, the management of VERBUND and SmartHelio were delighted to observe the excellent coordination between their teams which sets a strong precedence to their future collaboration.

VERBUND, now, would deploy SmartHelio’s predictive analytics software on a larger solar asset for real-time analytics and evaluate that, in the long-term, how such technology could inherently change their asset management practices.