“The future depends on what you do today.” – Mahatma Gandhi

The rise of predictive analytics and preventive maintenance in the solar industry has gained significant attention in recent years. Indeed, in a rapidly expanding industry, with the US solar market projected to grow by 20% and Europe’s solar capacity estimated to double by 2030, the urgent need for digitalization and predictive analytics becomes evident to effectively manage and ensure optimal performance of solar installations at scale.

However, amidst this constantly increasing buzz, which recently reached a new high at Intersolar Europe 2023, there are misconceptions that should be addressed to truly understand the essence of these terms and ensure we are all talking about the same thing. At SmartHelio, we are committed to providing accurate and actionable insights to help solar industry stakeholders de-risk investments, maximize performance, and reduce costs. Staying true to our mission, in this article we will demystify predictive analytics and preventive maintenance and shed light on their true meaning.

Understanding Predictive Analytics

Predictive analytics in the solar industry is not only leveraging historical labelled data and advanced algorithms to forecast production and predict major component failures like inverters. It also includes the understanding of the early signs of underperformance based on system behaviour anomalies. Predictive analytics encompasses the analysis of a fault’s behaviour with time and projected losses associated with it which helps in prioritizing the proactive actions to be taken.

By analysing past data, understanding the real-time electrical patterns in combination with weather patterns, solar irradiation, and system parameters, predictive analytics can enable the identification of potential issues before they cause significant performance loss and possible equipment failures. SmartHelio’s Autopilot platform uses physics-informed AI, combining Machine Learning techniques with domain expertise, to deliver reliable and accurate predictions and insights.

“Whereas physics-based models are very good on post failure analysis, with more Machine Learning knowledge in our data warehouse we will then be able to recognise very small deviations at an early stage to have prediction on where your next fault may probably happen”

– David Ebner, Project Engineer at VERBUND

Relying solely on AI for predictive analytics in solar, without considering physics-informed models, falls short in several ways. Depending on historical data alone neglects real-time changes, emerging trends, and unforeseen scenarios. It can lead to incomplete understandings, biased predictions, and inaccurate results. By integrating physics principles into AI models, a more comprehensive and reliable approach to predictive analytics in solar is achieved, debunking other solutions who solely rely on AI whilst neglecting consideration for the underlying physics.

“When trying to overcome these barriers in today’s AI methods researchers turn back to an old principle of technology development – understanding nature and learning from it. They ask, how can we build AI systems that can tap into the knowledge we have about the physics of our world?”

– Olympia Brikis, Head of Physics-Informed AI at Siemens,

‘The hidden Potential of Physics-informed AI’ 2022 Siemens

The Essence of Preventive Maintenance

Preventive maintenance is a critical aspect of ensuring optimal performance and longevity of solar installations. It involves taking proactive measures to prevent equipment failures and mitigate potential risks of underperformance. Preventive maintenance today focuses mainly on regular inspections, servicing, and repairs of the mechanical and electrical infrastructures of a PV plant. However, these regular inspections are often periodic based, not issue focused, or can be investigative in a broad sense only after a failure or underperformance has been identified.

Lacking data-driven intelligence, such interventions are not an efficient but reactive use of resources, and they come at significant cost. For example, preventive maintenance based solely on regular interventions cannot consider data-driven intelligence that may detect component behaviour anomalies. By incorporating real-time data analytics, predictive maintenance can optimize performance by identifying and addressing potential issues before they escalate, ensuring optimised system performance and reducing unnecessary maintenance activities and cost.

How is it working?

In solar preventive maintenance, we can draw a parallel to tachycardia, a condition that signals an impending heart attack. Just as specific heart frequency patterns indicate an issue, regardless of who the person is, anomalies in solar component behaviour, such as inverter shutdown or tracker malfunction, can be detected early.

By recognizing these patterns, proactive measures can be taken to prevent system failures and optimize solar plant performance. Similar to understanding the biology of the heart to be able to detect a heart attack, one must deeply understand the physics of solar to make sense of the electrical patterns.

By identifying and addressing issues at an early stage, preventive maintenance minimises downtime, improves energy production, and reduces maintenance costs. SmartHelio adopts a comprehensive preventive maintenance strategy that goes beyond relying solely on SCADA/monitoring alerts. We proactively assess equipment health, provide recommendations based on data-driven insights and prompt preventive maintenance scheduling based on component information analytics developed over 5GW of global assets management.

Monitoring vs. Analytics in Preventive Maintenance

It is important to understand the distinction between monitoring and analytics in the context of preventive maintenance. Monitoring involves real-time data collection and basic alerts that provide immediate information about the current state of the system. Whilst monitoring is essential for detecting immediate issues, it lacks the in-depth analysis and long-term insights that analytics offer.

Analytics, on the other hand, involves advanced data processing, correlation analysis, and predictive modelling in order to provide technical, financial and economical actionable intelligence. It uncovers hidden patterns, identifies trends, and provides actionable insights for preventive maintenance planning. SmartHelio’s Autopilot platform empowers monitoring systems, enabling granular analysis, accurate fault predictions, and data-driven decision-making for efficient preventive maintenance strategies. The plug-in software platform integrates seamlessly with the existing SCADA or CMS monitoring system in order to automate and accelerate accurate fault classification, failure prediction and action prescription.

“Increase PV power generated by the panel is one value. There was a series of ground fault, which may cause over-voltage and even fire risk […] Safety is number one priority for Schneider. We see safety improvement as a second value to (SmartHelio’s) technology”

– Luc Hossenlopp, CTO Digitalisation at Schneider Electric

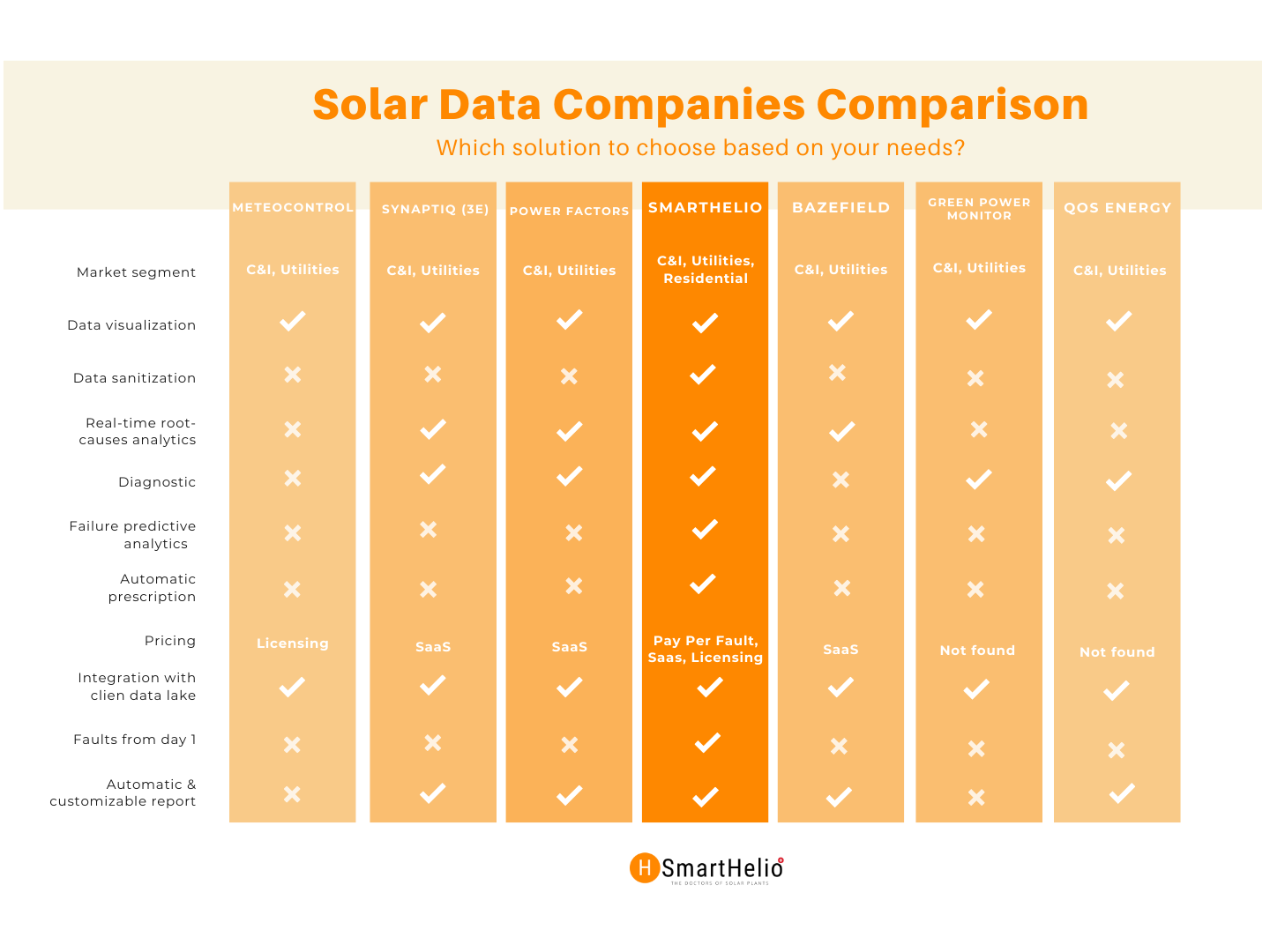

Differentiating SmartHelio as a Reference in Predictive Analytics

To truly understand the meaning SmartHelio attributes to predictive analytics, let’s explore concrete use cases in action

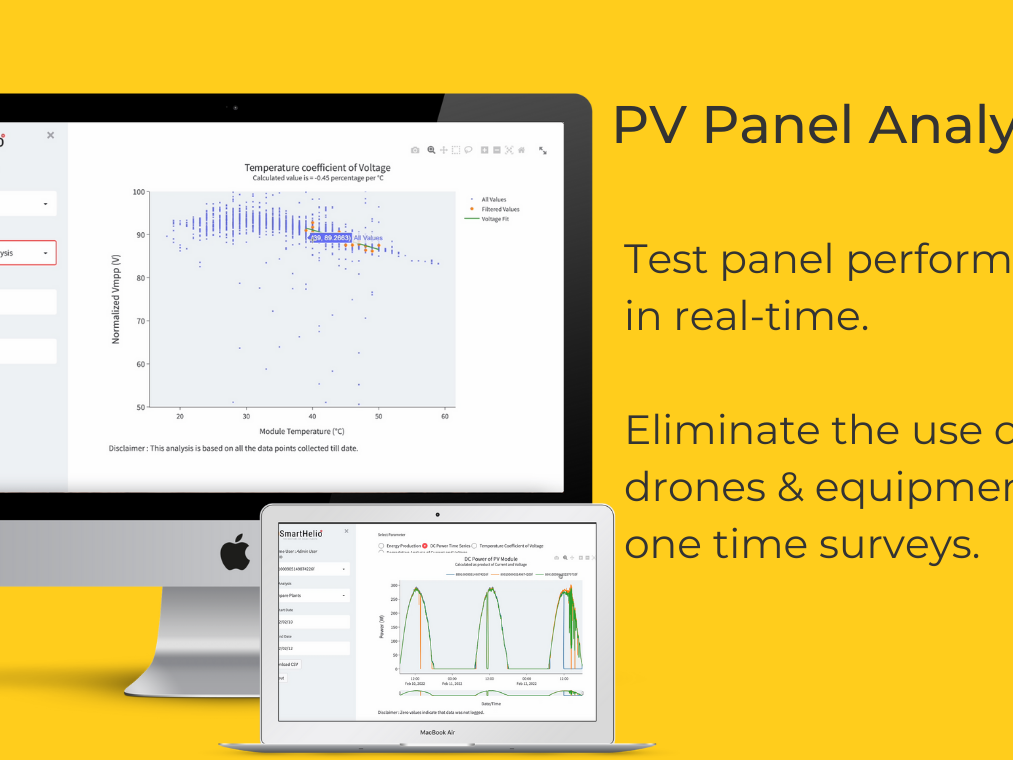

Early Detection of Declining Panel Efficiency

By analysing historical data and tracking performance trends, SmartHelio’s predictive analytics algorithms could identify gradual reductions in panel efficiency. In our latest finding from a 75MW site in Italy, our software detected 0.78% higher degradation at the end of 3rd year since commissioning.

This early detection enabled timely interventions and warranty claim coordination with the OEM to ensure optimal performance and maximize energy production.

Predicting Potential Faults in the Inverter System

Leveraging physics-informed ML models, SmartHelio’s analytics platform identified patterns and anomalies in inverter system data. Overheating issues were detected as the probable cause. Our predictive intervention avoided significant resources to find the root cause & fix the failure of this 1.75MW inverter.

By detecting potential faults before they occur, our platform enabled proactive, targeted maintenance, reducing downtime and avoiding costly system failure losses (~EUR 787 per day).

Optimising Trimming Schedules Based on Vegetation Rate Projection

SmartHelio’s advanced analytics considered utilized advanced pattern recognition algorithms to detect evolution of horizons profile. Supervised ML models then identified pattern of vegetation, and optimized trimming interventions based on projected vegetation growth trends which was forecasted to be impact the performance by 0.018% per week in this 20MW plant.

By intelligently planning trimming operations, solar assets could maintain optimal performance while minimizing unnecessary trimming costs.

These examples highlight SmartHelio’s ability to deliver accurate and actionable insights, empowering solar industry stakeholders to make informed decisions and optimise their operations.

Conclusion

Understanding the true meaning of predictive analytics and preventive maintenance is crucial for today’s solar industry. Leveraging its value will enable solar industry stakeholders to de-risk investments, maximise performance, and reduce costs. SmartHelio’s commitment to providing accurate and actionable insights sets us apart as a benchmark in the industry. Through early fault detection, optimised maintenance strategies, and reliable predictions, SmartHelio empowers decision-makers with data-driven approaches for a sustainable and efficient solar future.