SmartHelio: The Doctors of Solar Plants

SmartHelio, the Solar Doctor

Article originally from Efficience 21 in collaboration with CleantechAlps.

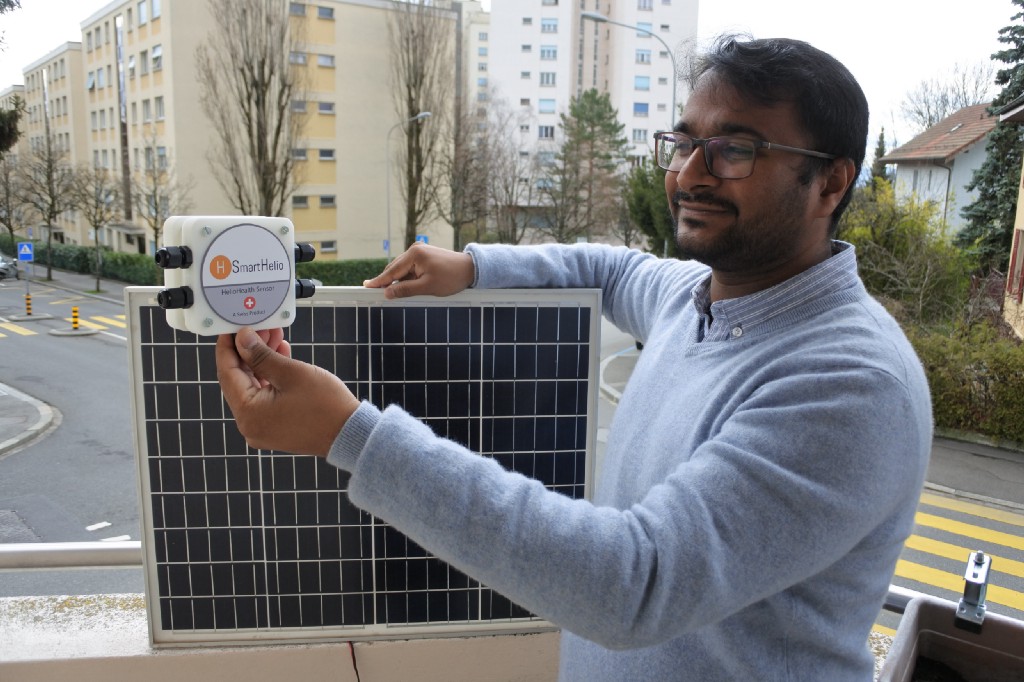

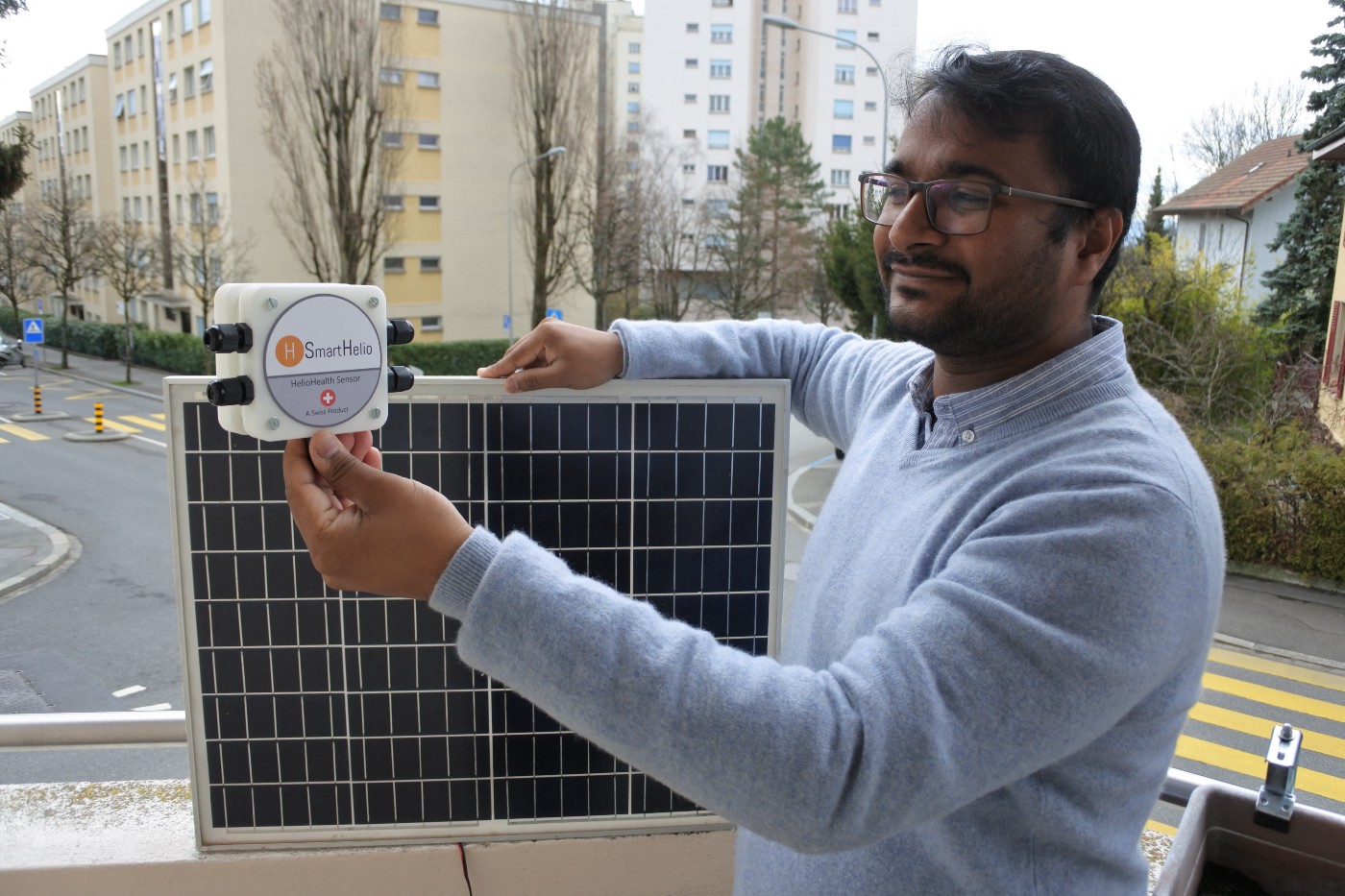

“The young entrepreneur, Govinda Upadhyay, imagined an innovative system, that can diagnose faults in solar plants based on the data collected from their smart IoT sensor.

In order to optimize a solar plants’ efficiency, SmartHelio has developed a cloud based system to analyse their performance. This innovative system then provides prescriptive actions to fix the faults and improve energy production.

“Just like a doctor, our sensor ensures solar panels work properly and generate more kWh per day”, says Govinda Upadhyay, CEO of SmartHelio.

The start-up was created in 2019 in Lausanne, Switzerland and currently employs three people.

SmartHelio solution — an AI-enabled sensor, is made up of three modular components: a communication module compatible with different protocols (WIFI, GSM, LoRa and BT), a encrypted processor and, most importantly, a fault detection device. For the time being, the detection device just captures current and voltage data, but in the near future, it could take into account more parameters such as pollution, air temperature or soil humidity.

Diagnostics and Prescriptions

Pattern recognition technology is being used in the sensor developed by SmartHelio which can identify faults in solar plants. By measuring the variations of current and voltage, the technology anticipates and prevents failure of the system. Their algorithm is based on clear sky moment detection that helps the AI to detect shading events, panel soiling, module degradation etc. Ten years of research has gone into this project to develop such AI where the data has been collected from solar plants from all over the world.

Beside its affordability, what makes SmartHelio solution so different from competition is how data is being processed and analysed automatically.

“Many monitoring systems already exist, but they are all expensive and can only collect data, but they are not able to perform root-cause analysis as SmartHelio does.” SmartHelio system can also use data coming from several sources and other monitoring platforms; in addition, it does not necessarily require weather station to assess solar plants performance, unlike competitors.

Taking things up a notch

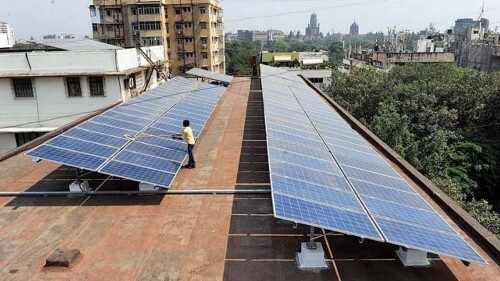

After a few tests in Switzerland, the company decided to focus its activity in emerging markets such as India, where solar energy industry has a 34% growth (CAGR), representing 10 billions Swiss Francs. Currently, SmartHelio has more than ten clients and currently monitors a 20MW portfolio.

In Europe, the start-up has two clients in France and one in Switzerland. During the covid-19 crisis, its activity has increased 200%; lots of solar plants owners were looking for a system capable of analyzing data in a reliable and precise way to remotely diagnose their systems.

A CEO known for his sustainable innovations

It is not the first time that Govinda Upadhyay innovated in the solar industry: his first start-up, LEDsafari, offers a DIY solar lamp, combined with a online training platform, which has impacted so far more than 100,000 people in the world.

Thanks to that invention, Govinda won in 2015 the EIT Change Award; in addition, he was listed among the Forbes “30 under 30” and the Asia 21 Young Leaders. He has also received the prestigious Swiss Ambassador Award for his work in sustainability.”

Thank you Efficience 21 and CleantechAlps for this article about the journey of SmartHelio and its founder, Govinda. Check out the original article, written in French, here!

Solar reimagined using AI & machine learning

Re-think and Re-imagine solar using Artificial Intelligence and Machine Learning

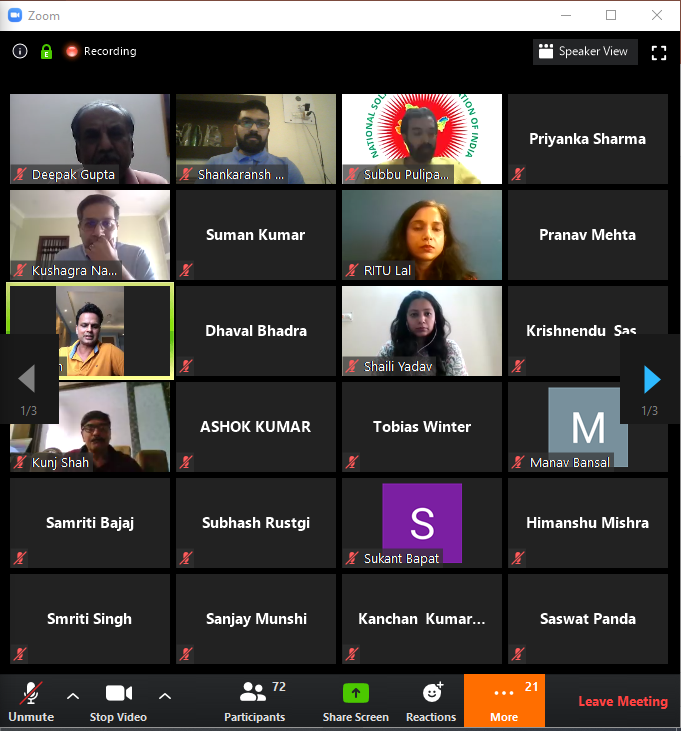

In the past one month, most of us had to restructure the way we work. From the discipline of working from home to virtual meetings, we have successfully adapted to the calling. Webinars have increasingly become a source of knowledge sharing, problem solving, industry wide discussions and collaborations. Organizations like NSEFI, SolarQuarter, Bridge to India, Mercom etc played a vital role in hosting seminars on the impact of COVID-19 on the solar industry and the way forward.

During these webinars, many industry leaders like Amplus, SunSource, Aditya Birla, Zodiac Energy, TATA Power, Fourth Partner etc shared their problems and how the lockdown has impacted their businesses. Focusing on the problems with the solar plants (constructed and operational pre-lockdown), here is a quick summary of COVID-19 impact:

1. Many C&I solar rooftops have been shut down because these buildings (factories, schools etc) are shut.

2. Such C&I projects with the OPEX model have choked the revenue of IPPs.

3. Projects built under government tenders have PR guarantee commitments but due to lack of manpower or restricted movements, cleaning schedules have been affected.

4. Some plants which are still operational during the lockdown had maintenance scheduled post March 25th, but again, they could not be served on a timely manner now leading to further decreasing performance of these sites.

5. Rooftops got very little share of the voice, focus was diverted towards utility scale plants.

India installed 1700MW of rooftop capacity in 2019. 90% of this capacity installation came from the Commercial and Industrial (C&I) segment. Although developers are worried that all facilities are shut down because of the current lockdown, they appear to be taking measures to ensure revenues continue to flow1. On the other hand, the rest 10% of the smaller residential rooftop installations are predominantly accounted for by 10–15 leading players. In conversation with one of the leading residential rooftop players- Zolt Energy’s CEO Harsha Yadav, he mentioned that the residential subsidies are delayed, some signed contracts are getting cancelled, for quite a few ready-to-install contracts they had already procured materials for installations which are now either sitting in their warehouses or stuck in logistics.

Leading rooftop C&I players expressed their concerns over the post-lockdown O&M challenges:

1. C&I solar rooftop buildings will operate in a staged fashion wrt their energy needs and so turning on the solar PV has to be staged as well, but there is no such insight to the best approach to activating small arrays at a time.

2. O&M services will pile up, so how should one prioritize to maximize the revenue and keep the end-customer engaged and happy.

3. The availability of labor/staff for cleaning panels or regular O&M would be limited, so how can one efficiently manage their available workforce.

One could sense that these problems have given an opportunity to the solar companies to rethink their cost structures, O&M, resource allocation etc. This lockdown helped create a space for solar companies to realize the inefficiencies with the O&M of solar plants.

NSEFI CEO, Subrahmanyam Pulipaka says- “COVID19, a black swan event, has a potential to change the entire paradigm of the rooftop business models in India. This will definitely pave the way for innovative business models and inculcating both cost effective and revenue inducing practices throughout the solar plant development ecosystem. Out of all the elements of rooftop plant commissioning, O&M which is often neglected will also be a direct witness of this paradigm shift and Indian rooftop sector will further move towards intensified digitization of assets and their administration in the coming months.”

Solar companies in India have started to realize the need for building an O&M approach that’s futuristic in nature. Through speaking with several companies and via several webinars, the following requirement were noted:

1. Shift from the manual approach for O&M to an automated and predictive maintenance schedule to maximize the system performance and revenue.

2. End-customer engagement and awareness of their solar assets.

3. Focus on sustainability of the solar assets by building a data driven framework for: product selection, system design, dynamic production estimates, faster fault localization and system degradation identification at early stages.

Companies around the globe have already started using deep-data analytics and with the help of AI and Machine Learning, they have already started optimizing their operations and maximizing their revenue. John Deere was able to save $1 Billion by optimizing their inventory2, Best Buy used deep-data analytics to redesign their stores to increase in-store experience3, UPS is utilizing Machine Learning, AI and Big Data to identify and predict problems in their logistics4, and the list continues.

Hinduja Renewables’s CEO, Kapil Maheshwari, emphasized, in one of the webinars, the importance and need to use technologies like AI to perform root cause analysis and data analytics to identify specific concerns in a solar asset. Most of the solar companies in India, currently use excel sheets to generate basic data analytics which only serves to manage reactive maintenance issues. All solar companies use data visualization tools which provide fault alerts, these alerts are analyzed by an engineer and then coordination with the on-site technician takes place to localize the fault and finally steps to rectify the fault are planned. This leads to increased system downtime and lost revenue.

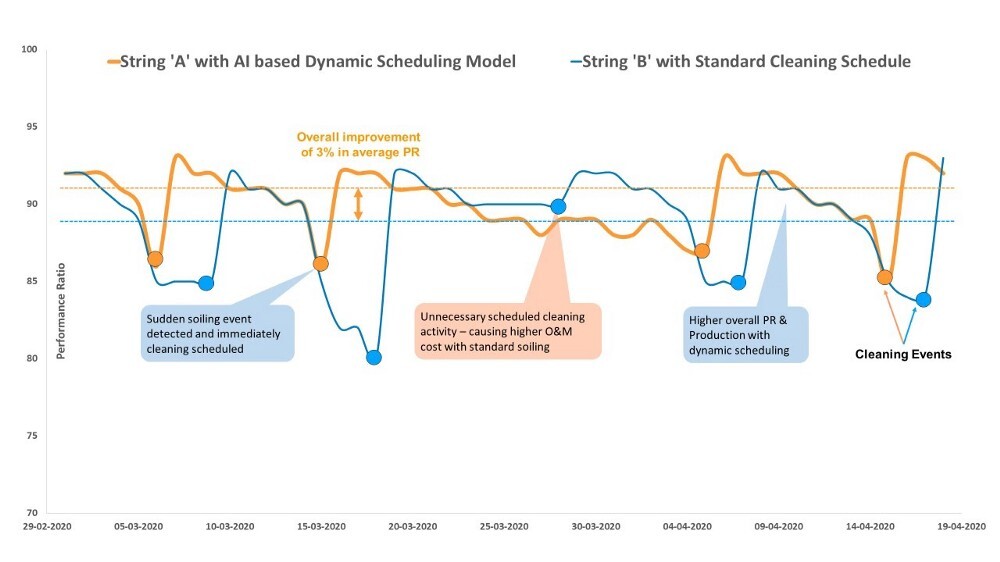

Artificial Intelligence models help localize the faults automatically, learns system behavior, predicts system’s performance and prescribes steps to maximize solar production and hence revenue maximization. Advanced AI models use dynamic pollution modelling and climate change factors to estimate realistic energy production, suggest dynamic cleaning schedules, accurately intercept shading losses, and monitor the electrical characteristics of your plant to predict its behavior. AI can also help solve the problem of unidentified module degradation due to high temperature, PID, hot spots etc. by detecting them at a very early stage so that the bad guys could be taken out of the system and save the performance of the rest of the system from being affected.

SmartHelio is working with solar companies in India, Europe and North America to bring a shift from reactive maintenance to data driven predictive maintenance with an ultimate goal of making the solar PV systems more sustainable for the entire ecosystem.

Author: Shankaransh Srivastava, Business Development Manager at SmartHelio

Co-authors: Govinda Upadhyay, Founder and CEO of SmartHelio; Subrahmanyam Pulipaka, CEO of National Solar Energy Federation of India (NSEFI)