Decoding Digital Twins for Solar Power Plants

Investment in solar energy projects has increased in recent years and so has the use of advanced solutions for optimizing solar operations and maintenance like Digital Twin, edge computing, and IoT. We are decoding the concept of Digital Twin in this article and explain to you how Digital Twin technology is helping to transform the way solar plants function and operate.

With the use of advanced IoT solutions and smart sensors, now we can get solar panel-level data insights on any kind of solar plant. Detailed analysis of this data is used to design advanced solutions like Digital Twin. Effective use of Digital Twin can help solar asset managers detect early patterns of system underperformance, which later can be used to predict potential faults and quantify the impact of existing/upcoming faults or losses in solar power plants. Thus, Digital Twin techniques help solar developers anticipate solar power plant system’s future production, plan predictive and corrective maintenance activities, and improve the bankability of future projects.

What is Digital Twin in solar?

A Digital Twin is a virtual model of a real system. While changing the input variables, a Digital twin helps to conduct experiments and test hypotheses, as well as to predict the behavior of the solar power plant’s system and to manage its life cycle. A Digital Twin also helps to prevent equipment failures, and poor system design and minimize operating costs. In the specific case of the solar PV industry, a Digital Twin is a digital copy of the solar power plant, including all relevant design and location information, as well as information from the past; including major losses causes, and performance indicators breakdown.

Why do solar Asset Managers need Digital Twin?

Digital Twin is a faster way of comparing, at specific conditions, PV plant’s current performance with its expected performance drawn from its digital copy. After a Digital Twin of a Solar PV Plant is created, the only required inputs, other than real-time plant data, are irradiance and temperature. Therefore, performance and loss analysis becomes faster and easier to perform. More advanced solar PV plant Digital Twins even include a parameters breakdown and trends to indicate root causes of faults or losses in real-time. Thus, making daily tasks easier for solar Asset Managers and increasing the uptime of the solar plants.

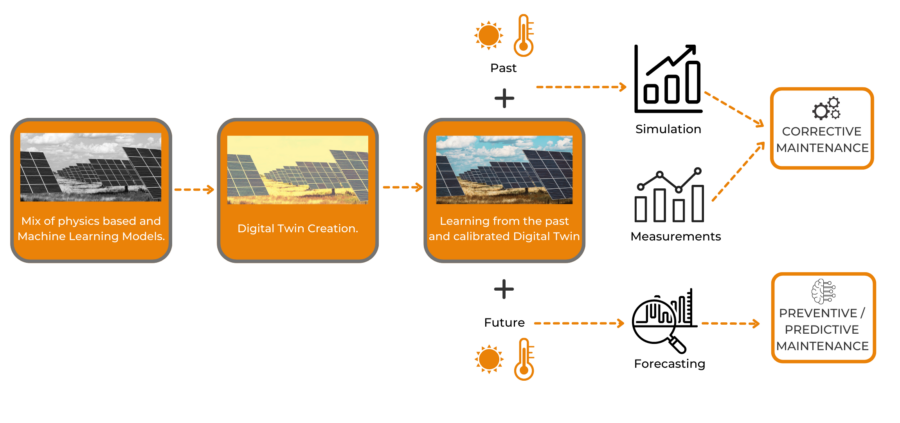

How do you make a solar Digital Twin?

A Digital Twin is a virtual instance of a physical system (twin) that is continually updated with the latter’s performance, maintenance, and health status data throughout the PV solar power plant’s life cycle. A Digital Twin looks like, behaves like, and connects to a solar plant system with the goal of improving or optimizing decision-making for any time horizon. It should be localized by considering the geographical position of a solar power plant, locally measured power and weather data, and power loss factors.

An ideal Solar Digital Twin should be self-adaptive, that means, it should be able to modify and recalibrate its behaviour and likeness under changing operating and external conditions, such that it satisfies operational goals and constraints to accommodate possible future operational uncertainties.

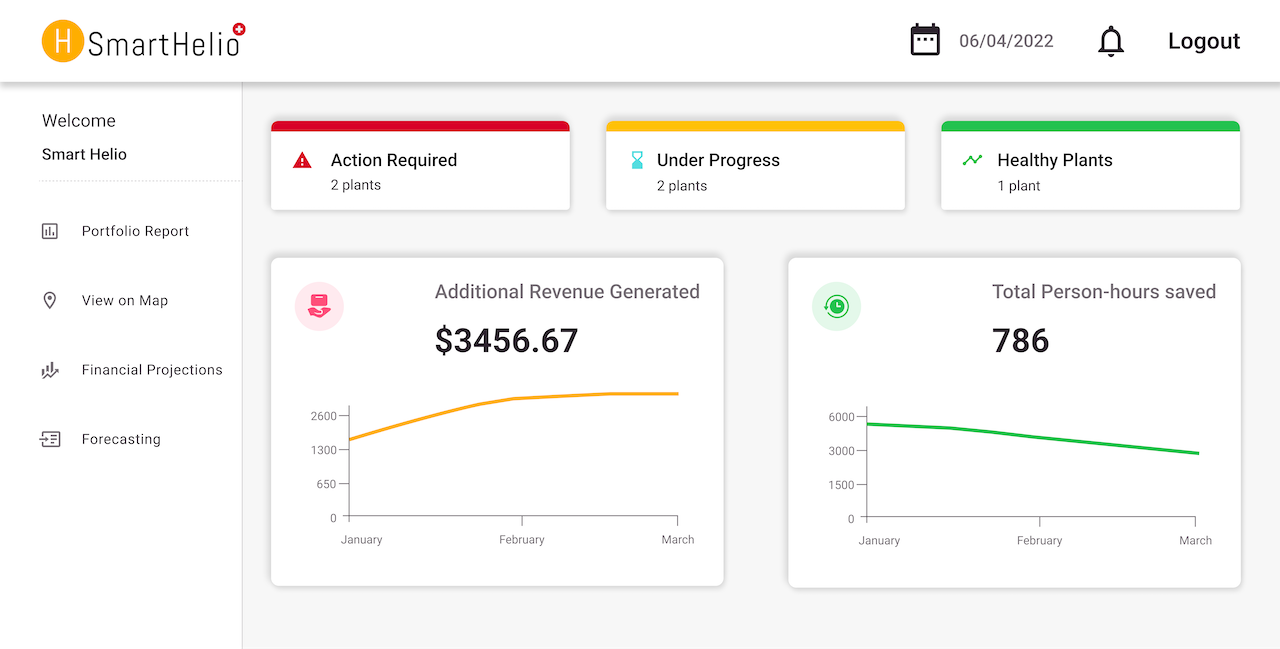

How SmartHelio uses Digital Twin?

In general terms, creating a solar Digital Twin is a faster way to detect even the smallest deviations in performance and make sense out of different trends within the historical data. At SmartHelio, we create and localize Digital Twins of solar power plants by adding design factors, geographical factors, and performance factors and trends. Our Digital Twin models automatically prioritize solar power plant maintenance activities to minimize O&M costs and maximize solar plant’s uptime. It’s a blend of advanced technology and continuous learning with a custom-tailored understanding of O&M costs and resources for each solar plant or company. Our Digital Twins do what a Digital Twin is actually supposed to do- directly derive actionable insights from any kind of solar power plant!

Planning to set up a Digital Twin for your solar power plant? Learn how our team can help you. Click on the button below to talk to our solar energy experts

and get a diagnosis of your solar plant today!

'Best for the World' recognition by B Lab

SmartHelio has been recognized as “Best for the World” by B Lab and topped the Environment category in Switzerland. Read to know more…

SmartHelio has been recognized as “Best for the World” by B Lab and topped the Environment category in Switzerland. Read to know more…

Deep-data analytics company SmartHelio, was recently recognised as “Best for the World” by B Lab. B Lab in its annual B Impact Assessment evaluated top-performing B Corps on five categories-community, customers, environment, governance, and workers. SmartHelio, with a score of 116.8, was recognised as “Best for the World” in the environment category.

“SmartHelio is a mission driven company and the impact on the environment is core to our daily operations. We are delighted that our efforts are being acknowledged by B Corp. We hope that more organizations will join this movement,” Govinda Upadhyay, CEO & Founder.

SmartHelio is among top three Swiss cleantech companies to be selected as ‘Best for the World’ in the Environment category. The company has excelled in environmental performance by offering advanced and effective digitization, AI and automation practices for effortless solar plant performance management and predictive maintenance. Our solutions make clean energy asset management and energy operations profitable and long-lasting.

What is ‘Best for the World’ recognition by B Lab?

Every year, B Lab recognizes the top-performing certified B Corporations creating great impact through their businesses. Once their verified scores in the five impact areas evaluated on the B Impact Assessment – community, customers, environment, governance, and workers – are amongst the global top 5% in their corresponding size group, these B Corps are named Best for the World.

Why is the B Lab ‘Best for the World’ recognition important?

The “Best for the World” recognition is important in the sense that chosen B Corps in the five different categories prove that the competing organisations are not only the best in the world, but more importantly the best for the world. Their actions inspire more businesses to join the movement that is transforming the global economy to benefit all people, communities, and the planet.

To achieve B Corp certification, a company must meet these rigorous criteria:

- Demonstrate high social and environmental performance by achieving a B Impact Assessment score of 80 or above and passing our risk review

- Make a legal commitment by changing their corporate governance structure to be accountable to all stakeholders, not just shareholders, and achieve benefit corporation status if available in their jurisdiction.

- Exhibit transparency by allowing information about their performance measured against B Lab’s standards to be publicly available on their B Corp profile on B Lab’s website.

“We have always kept climate-conscious innovation at the core of our company. In our technological offerings or in our business models, we have institutionalized certain measures where we always assess our performance in terms of contributions made to the climate or environment. This approach has truly helped SmartHelio to be among the global front-runners in climate and environmental sustainability,” Neeraj Kumar Dasila, Co-Founder & Chief Technology Officer, SmartHelio.

SmartHelio partners with international research project GENTE

We are proud to announce that SmartHelio is a Technology partner of an international research project GENTE. GENTE brings together an international consortium of highly qualified partners comprising need owners, citizens, scientific partners, technology providers, living labs, and technology demonstration sites.

GENTE is a multi-million dollar, multi-national project. The project aims to develop services and applications (the LEC toolbox) for Local Energy Communities (LECs) to improve their abilities to optimize, control, and manage energy resources in a federated manner. It leverages advanced technologies, including the internet of things (IoT), distributed ledger technology/Blockchain, edge processing, and artificial intelligence for autonomous energy resource management. The LEC toolbox will automatically implement the optimization strategies to control and manage the energy mix at the LEC level. It will minimize the grid dependencies for local power needs, significantly reduce the power curtailment by the grid, and maximize the injection of electricity into the grid considering the flexibility and stability provisions of the network.

The project also aims to bring intelligence to distributed energy assets by considering users’ behaviors, data privacy, and interoperability. The project will deliver a decision support tool and innovative services to the LECs that will enhance the economic viability of LECs and promote engagements of end-users and self-governance. The project will be implemented and validated in 6 different sites across three different countries.

The GENTE project has received funding in the framework of the joint programming initiative ERA-Net Smart Energy Systems’ focus initiative Digital Transformation for the Energy Transition, with support from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 883973.

Disclaimer: The content and views expressed in this article are those of the authors and do not necessarily reflect the views or opinion of the ERA-Net SES initiative. Any reference given does not necessarily imply the endorsement by ERA-Net SES.

Empowering solar asset managers through predictive maintenance

Inefficiencies related to solar PV plant management and O&M can be handled using effective digitization, Artificial Intelligence, and automation practices. Read to know how predictive maintenance can empower solar asset managers

Solar Photovoltaic is the most preferred alternative clean energy asset. In the last couple of years, it has seen a massive deployment across the world with an average annual capacity addition of 180 GW which is expected to triple by 2030. The growing capacity of solar photovoltaics is a great news but contrarily, it is also making the solar asset management a tedious job and, in the existing ecosystem, it is bringing down the operational efficiency of asset maintenance which is subsequently limiting the overall performance level of the solar PV plants. This is a worrying phenomenon for investors. The existing asset management tools and Standard Operating Procedures (SPOs) are limited and not effective enough to utilize the possible potential of the solar energy assets. Some of the major problems related to solar plant’s operation and maintenance can be summarized below:

- Unable to detect the early signs of equipment failure or faults in the solar PV system which leads to system under-performance because of unknown reasons till it becomes significant enough to attract the plant/asset manager’s attention. But by this time the asset has already lost a substantial revenue.

- High manual dependence on the O&M process limits the O&M teams from acting on time which leads to a higher turn-around time from the Fault Appearing to Fault Resolved. In solar industry, in some cases, we have seen a fault resolution period of up to several months.

- The existing PV Asset Management practices are not optimized enough to maximize clean energy production and revenue. In most cases, the solar plant maintenance schedules depend on the convenience of the ground staff which leads to inefficient asset maintenance, system underperformance, and high O&M expenses.

We strongly believe inefficiencies related to solar asset management and O&M can be handled by introducing effective digitization, Artificial Intelligence, and automation practices. In our efforts, we have introduced An Autopilot for the solar PV industry. The Autopilot works as a virtual support assistance to the Asset Managers, Performance Managers, and Plant Managers. It continuously reads the plant performance data, weather data, satellite data, and any other 3rd party data that is beneficial for doing the performance assessment and root cause identification in real-time. Autopilot has a robust understanding of the solar PV system engineering and it uses Machine Learning to develop incremental intelligence over a period of time which makes it incredibly accurate and fast in terms of detecting the early signatures of system underperformance, predicting potential faults, quantifying the impact of existing/upcoming faults/issues and dynamically scheduling the on-ground interventions by technical work-force (human and machines). With Autopilot we can see an overall improvement in solar assets’ performance by 15% (over their lifetime) and a reduction in O&M and Asset management costs by more than 50%.

As a stepping stone into the future of solar photovoltaics and other alternative clean energy assets, we believe if machines can manage themselves and can autonomously operate thousands of miles away in the extraterrestrial space then why can’t solar plants run autonomously using software like Autopilot. We see a vision to put each and every solar energy and other clean energy asset in Autopilot mode once they are commissioned.

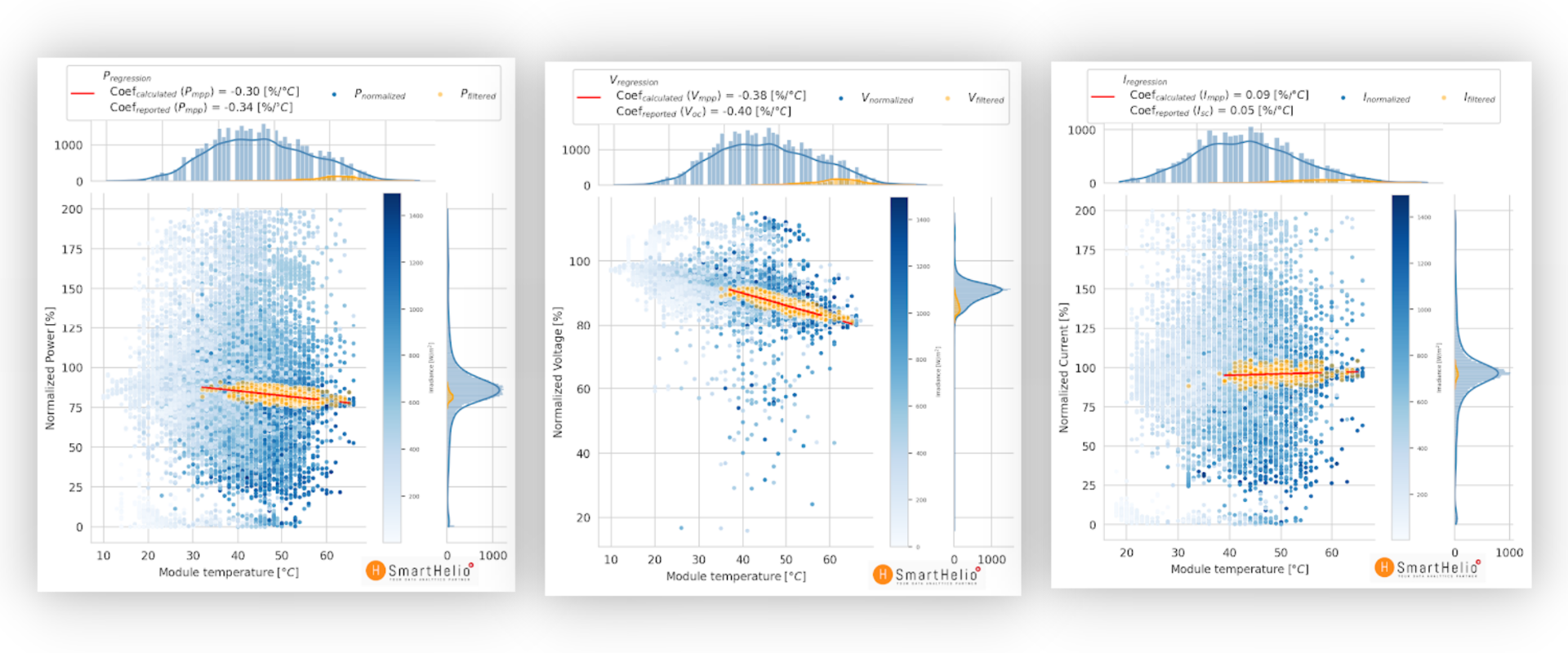

Do you validate your solar PV module's thermal coefficient?

This technical research paper highlights sensitivity of the PV Modules towards rising temperature that negatively impacts the electrical conversion efficiency of a solar PV module and thus overall performance of the plant. Read to know more.

A solar PV plant system is based on a simple mechanism that converts sunlight into clean energy. However, the process is not as simple as it seems. Some of the incident energy falling on a solar PV panels is reflected and some other is dissipated as heat, causing the solar PV module to operate at a higher temperature rather than at ambient temperature. This rise in temperature of the solar PV modules can affect the energy production and overall performance of your solar power plant.

The aim of our research was to study the sensitivity of the PV Modules towards rising temperature that negatively impacts the electrical conversion efficiency of a PV module and thus overall performance of the plant.

During our research to determine a PV module’s sensitivity towards the rising PV module temperature, we compared the thermal coefficients specified by the PV module manufacturer in the specification sheet with the thermal coefficients calculated by SmartHelio’s team.

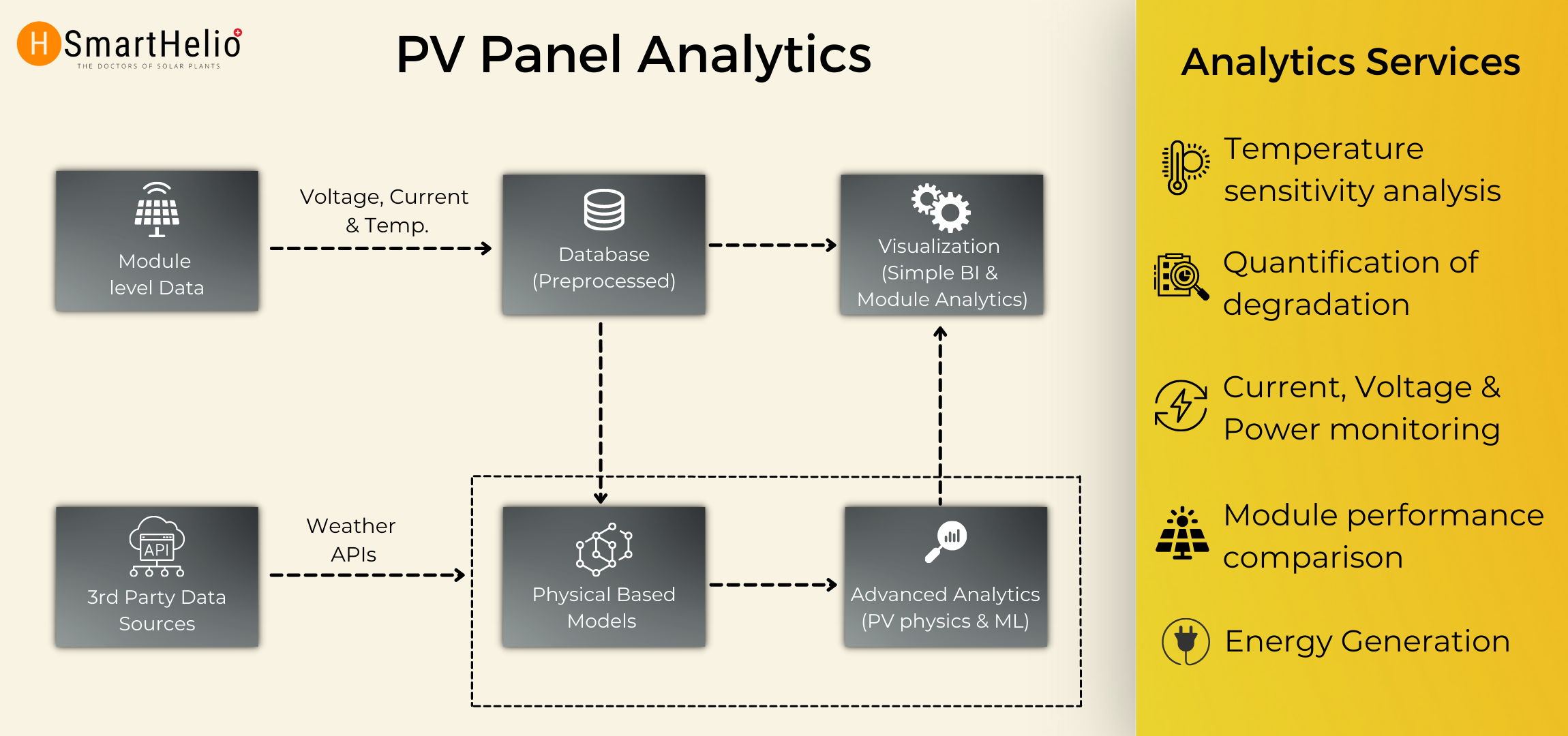

Our team through rigorous research and validation developed a PV Panel Analytics Tool that provides access to real-time sophisticated analytics such as thermal coefficients and PV module degradation to its subscribers, by accessing the real-time raw data with a precision of seconds collected by our IoT devices. Our tool also helps your procurement team to find the most profitable PV module technology for your plant by comparing different technologies for multiple locations.

Read more about our research, Click on the download button below to download our research paper ‘Validating Thermal Coefficients in Outdoor Conditions’

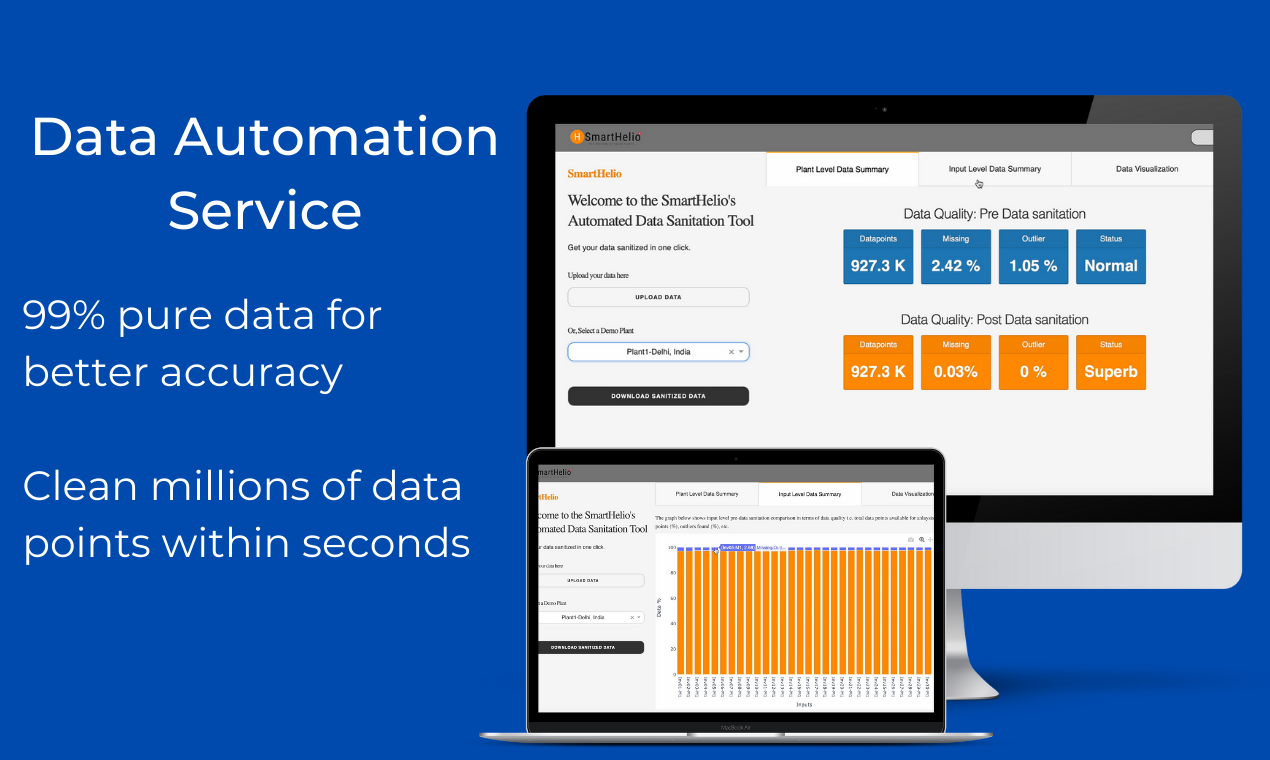

Clean millions of data points within seconds with AI-based data automation for solar plants

Missing data and poor data quality can have serious impact on your solar analytics and overall performance of your solar PV plant. Read to know how you can solve this issue using AI-based Data Automation technology.

As solar companies are shifting towards data-driven decisions, it becomes critical to have good quality data to ensure analysis is correct and actionable.

What is the role of data in solar PV plant’s performance?

Data not only helps you understand how your solar PV plant is performing in general but also helps to compare and analyze how different sections of the solar plant are performing in comparison to each other using performance indicators like PR, SY, soiling, degradation, etc. For example, data can tell you precisely if a panel is degrading faster than the other panel installed at the same site due to a shadow from the nearby tree. Data can derive intelligence for multiple stakeholders: Sales, engineering, procurement, management and investors. In short, data intelligence empowers a solar company to take informed decisions and plan their solar O&M in a better way.

The curious case of missing solar data points

Generally, a MW size of a solar PV plant produces 100,000 data points in a month. However, as reported by our customers in multiple geographies, 16-20% data points are usually missing in this data due to network or connection failure and/or faulty readings by the data loggers. Because of the huge quantity of data produced otherwise, missing data is usually ignored (an easy way out), thereby creating a void that leads to incorrect conclusions.

For example, missing data during the sunshine hours can effectively lead to low PR value in days of high energy production, or measurements during night time hours can give a high CUF value which is misleading.

Also, it is quite common to receive outliers/ bad quality measurements from data loggers, pyranometers due to soiling, bad weather conditions, calibration issues, etc. Generally, as a part of data cleaning, this data is removed from the dataset leading to data loss.

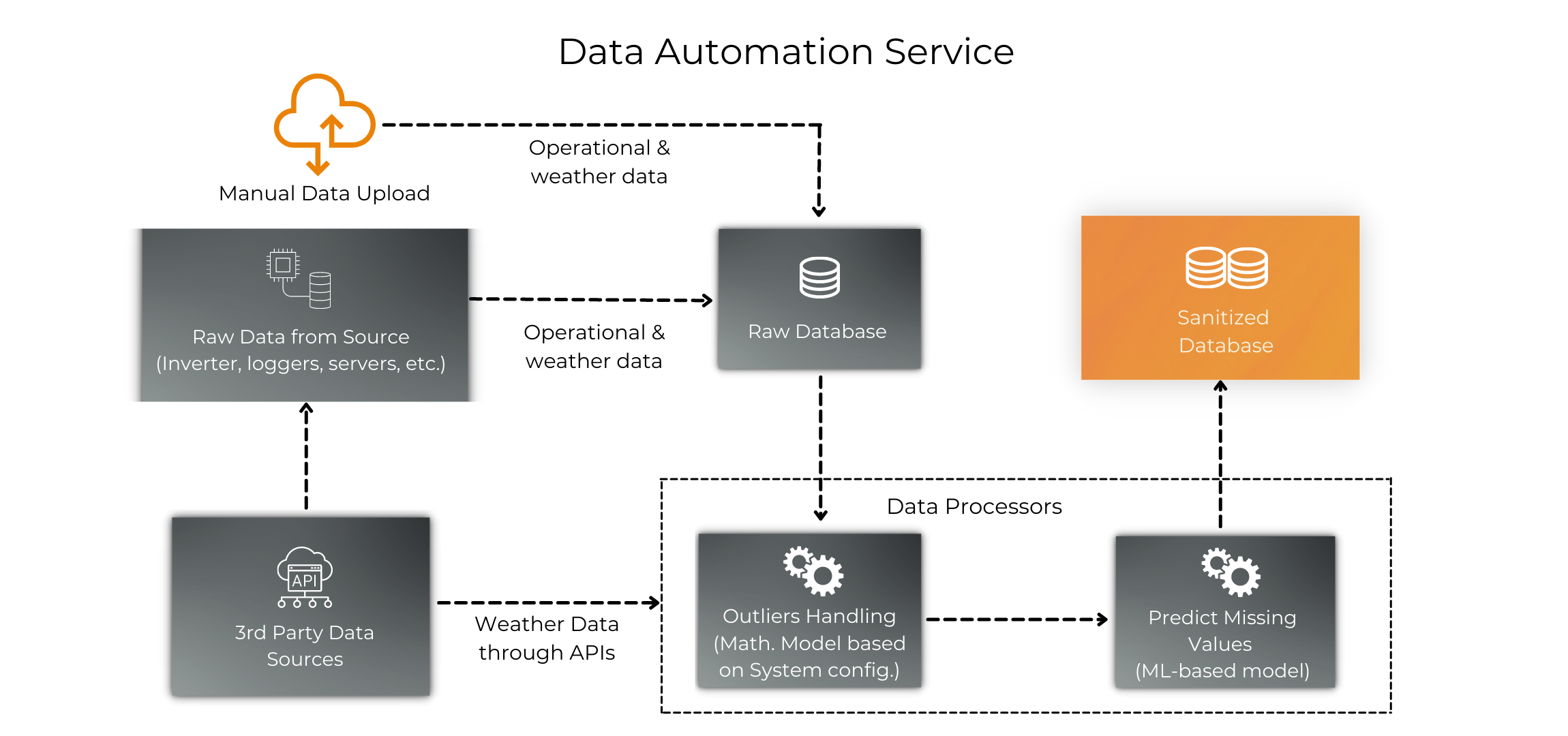

AI-based Data Automation tool for any kind of solar PV plant

SmartHelio’s Data Automation Tool aims to provide clean and sanitize data in a single click.

Our Data Automation tool is designed to clean and sanitize in a way to first remove bad measurements from the dataset and clean the dataset. It later predicts the missing data points with 99% accuracy using Machine Learning algorithms and provides sanitized data. All you need to do is connect your plant via API or upload your data to the tool and click “Submit”. You can simply download sanitized data and use it for your internal analysis.

To know more about our Data Automation tool you can book Ask Me Anything (AMA) session with our solar experts.

SmartHelio all set for the Y Combinator Demo Day

World’s fastest growing clean-tech company SmartHelio is now backed by Y Combinator. SmartHelio will be pitching its solution to a league of world-class investors during Y Combinator’s Demo Day. Read to know more…

It was a proud moment for the team when SmartHelio was selected for the Y Combinator startup program W22 batch. In a few days, on March 29th and 30th, 2022, SmartHelio will be pitching its solution to a league of world-class investors during Y Combinator’s Demo Day. The most awaited event for the startup community all over the world. The event will feature founders from 43 countries among the 375 startups selected for this batch.

With the rising concerns of climate change, innovative cleantech solutions are emerging rapidly across the globe. This growth is supported by investors who have invested $775 Bn in cleantech startups in 2021 and it is growing at 27% YoY. It is not only critical to replace fossil fuels but it is also important to make the current and future cleantech infrastructures truly sustainable.

What does SmartHelio do?

SmartHelio provides advanced predictive analytics and IoT solutions that help solar utilities automatically predict and prevent downtime disruptions, to increase their annual revenue by $10k per MW/ year from their solar plants.

What problem are they solving?

When a solar plant starts underperforming or shuts down suddenly, it directly affects the revenue of solar companies and operational expense increases. The main reason is the inability to automatically identify the reasons. This loss in revenue combined with increased operational expenditure amounts to a $15 Bn/year (and increasing) loss to the industry.

What is SmartHelio’s USP?

Minimize downtime and fix problems with click of a button. Their software reads the live data coming from solar plants, identifies why the plant is under-performing and prescribes actions to the companies with recommended timelines of action. This automation reduces manual interventions in maintaining the solar plants by 80%. If the plant’s data is not accurate, they also offer them their smart sensor IoT device.

Who are their customers?

Solar Developers, often called IPPs – Independent Power Producers (roof-tops and utility).

How did they get here?

The company was the brainchild of Govinda Upadhayay, CEO and Founder of SmartHelio, who is a serial entrepreneur listed in Forbes 30under30 for his work in the clean energy domain. He did his research in climate modeling from a top European tech university, EPFL, Lausanne. Govinda realised that the reactive maintenance of solar plants is affecting the health and its end-of-life. He started his research on designing an intelligent monitoring system that could keep a check on solar assets’ health. Thus, turning reactive maintenance to predictive maintenance for solar PV plants.

How has their journey been?

In just two years, SmartHelio bagged 15 international awards for its innovative solution and was selected by 8 prestigious acceleration programs. Recently, SmartHelio won the MassChallenge competition and was selected by the AWS Clean Energy Acceleration program. This year SmartHelio was also awarded the B Corporation Certification for meeting the highest social and environmental standards.

About Y Combinator

Y Combinator provides seed funding for startups. Every 6 months over 10,000 companies from across the world apply for the YC accelerator program, commonly called the YC Boot Camp. After critical evaluation by Venture Capitalists, only a selected bunch of companies make it to the three month long Boot Camp.

During these three months, YC works intensely with startups on their ideas helping founders deal with investors and acquirers. It helps startups to get into the best possible shape and refine their pitch to investors. Each cycle culminates in Demo Day, when the startups present their companies to a carefully selected, invite-only audience.

So far, more than 3,000 companies have been funded by Y Combinator like Airbnb, Coinbase, Dropbox, Reddit, Stripe to name a few. Many of these companies are now Unicorns.

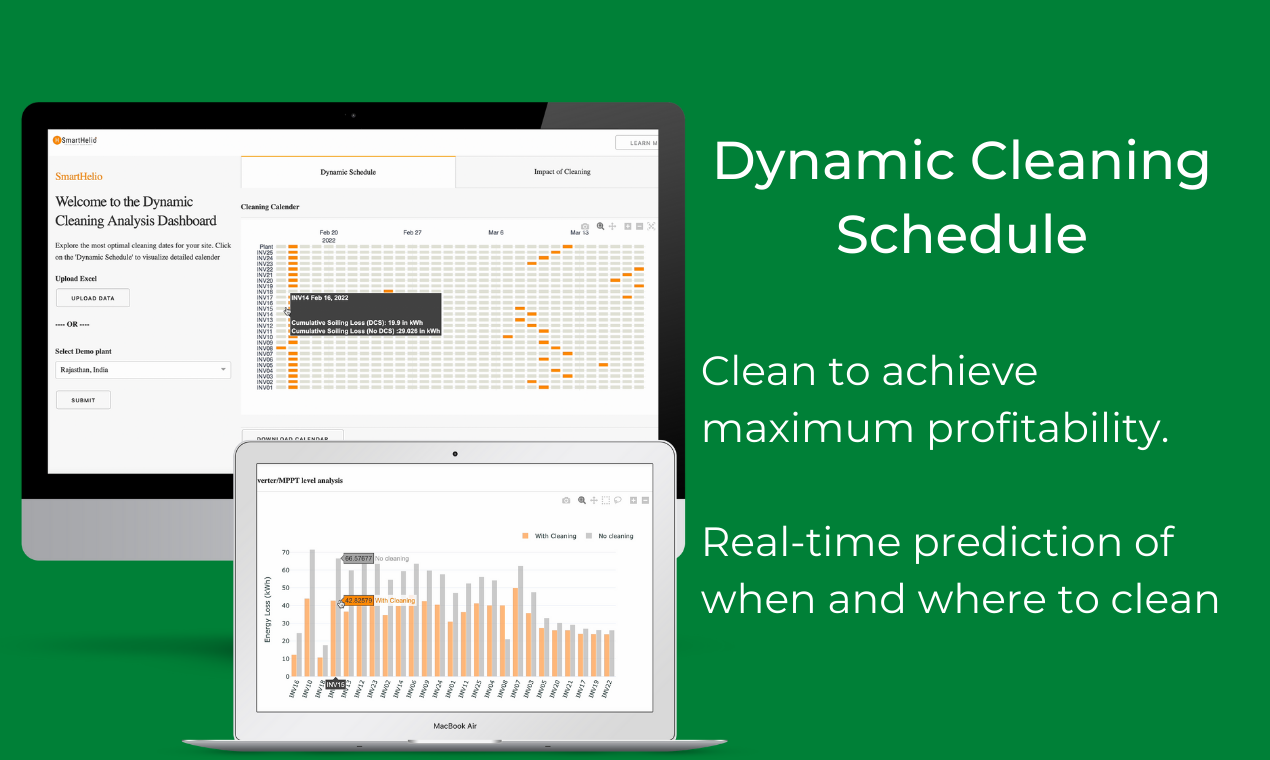

AI-based dynamic cleaning schedule for solar PV panels: A data driven cleaning approach

Solar PV Panel soiling commonly known as soiling losses impact clean energy production of solar power PV plant. Read to know what are soiling losses and how you can reduce solar O&M costs and track cleaning effectiveness of any kind of solar PV plant using AI-based Dynamic Cleaning Schedule.

One of the major roadblocks in solar PV plant’s performance is “Panel Soiling” caused due environmental and natural factors. Predominantly, deposition of dust, bird droppings, industrial dust, dust storm, snow etc. Such soiling causes reflection, absorption and partial scattering of irradiance which leads to reduced amount of solar energy that reaches the solar PV cell.

What are the effects of soiling on solar PV plant?

- Reduces the Energy Yield/Performance Ratio (PR).

- Increase in solar O&M cost.

- Induces more uncertainty in the solar energy production forecast.

- Decrease in the share of renewable energy in the market.

The estimated annual losses due to soiling ranges between ~2% and ~6% depending on the geographical location of the PV system. Therefore, an adequate methodology to mitigate soiling losses has become the need of the hour. Unlike other PV system losses, soiling is reversible i.e soiling can be mechanically removed from the surfaces of the solar panels either through natural means such as rain, wind or artificial means such as manual cleaning, semi-automated or fully automated robotic cleaning.

Robotic cleaning and manual wet cleaning of solar PV panels.

The most common anti-soiling technique adopted is the manual wet-cleaning of the entire plant as per fixed schedule. Globally, there has been a visible shift towards robotic cleaning adoption. However, the wide-area spread of the solar plants creates operational challenges for the solar asset managers. In most cases, the soil disposition across the plant is non-uniform and dynamic in nature. Moreover, meteorological events (like rainfall, snow, dust storm, etc.) play a vital role in the overall deposition of soil; hence, these factors should also be considered in the cleaning schedule. A fixed cleaning schedule that normally does not cover these factors, leads to inefficient cleaning and eventually leads to significant loss of energy production and resources (time, water, and labor).

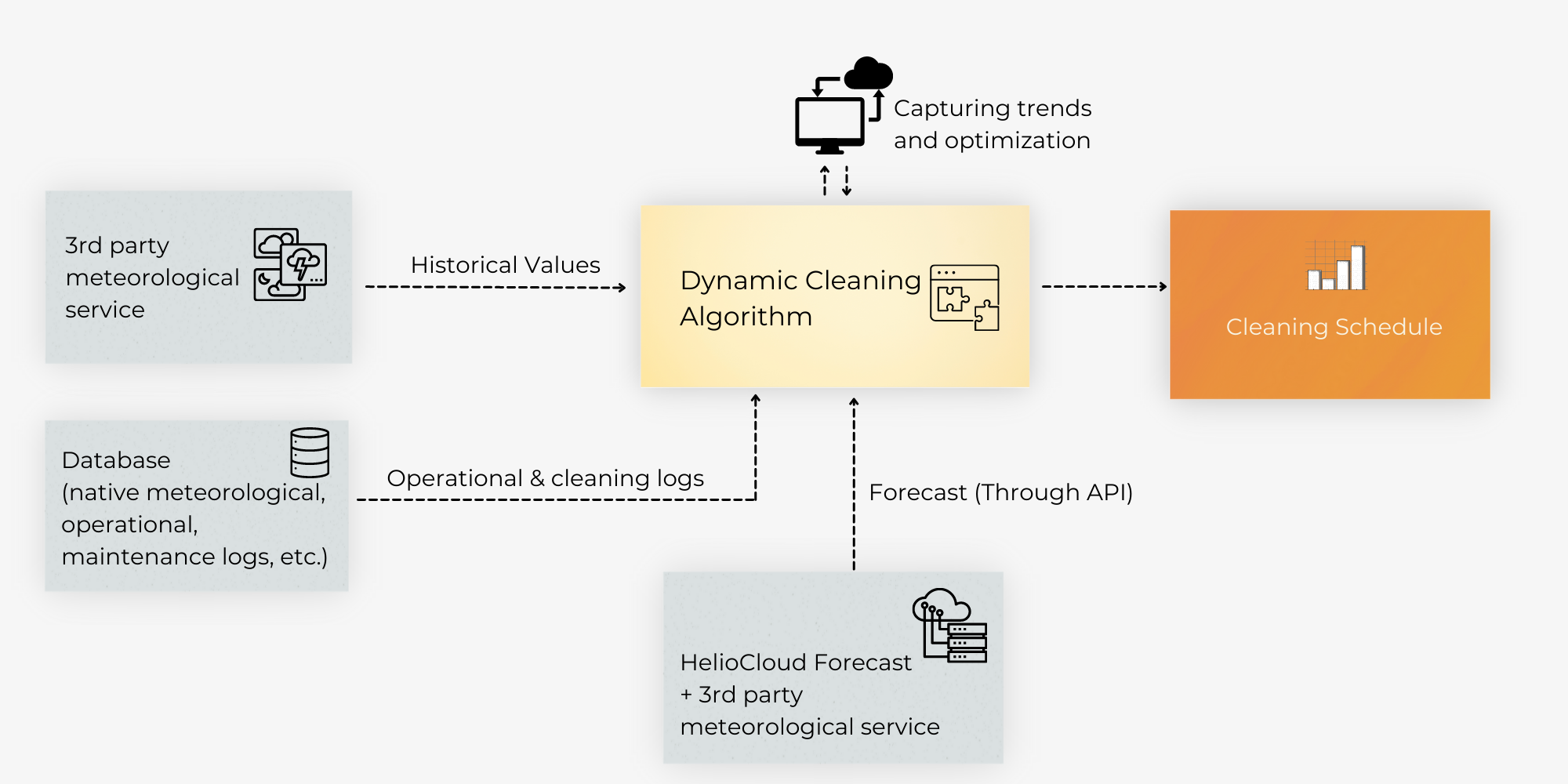

Smarthelio’s Dynamic Cleaning Scheduler

Smarthelio’s Dynamic Cleaning Scheduler takes into consideration soiling trends, meteorological events, cleaning cost and electricity cost and follows an Al-based optimization process to generate a dynamic cleaning schedule and track the cleaning effectiveness for different sections of the plant.

To know more about our Dynamic Cleaning Schedule tool you can book Ask Me Anything (AMA) session with our solar energy experts. Click on the button below to book your AMA session NOW!

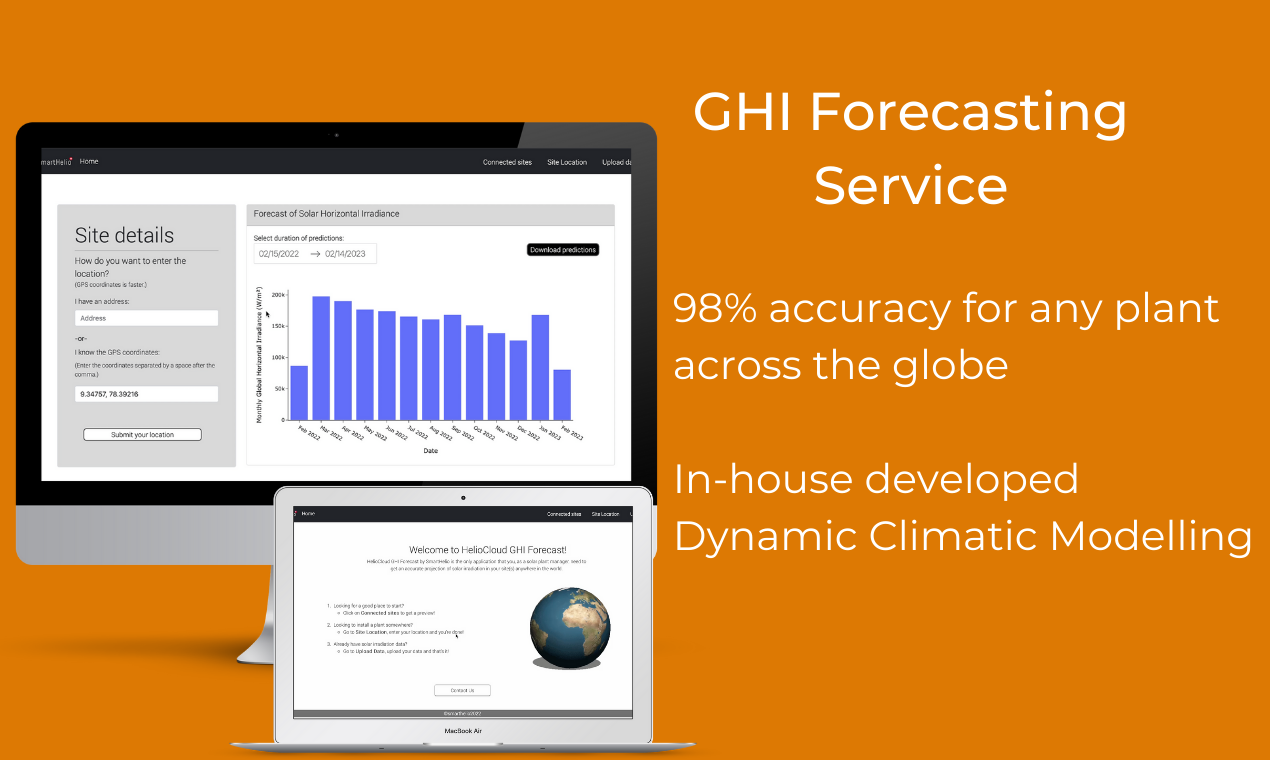

All you need to know about GHI forecasting for solar PV plants

Predict solar irradiance with 98% accuracy for any kind of solar plant across the globe.

SmartHelio’s HelioCloud GHI Forecast service is aimed to assist solar asset managers, banks and the like to obtain accurate predictions of global horizontal irradiance for any location in the world.

What is Global Horizontal Irradiance (GHI)?

Global Horizontal Irradiance (GHI), the electromagnetic spectrum obtained from the sun is the direct form of abundant energy resource that fuels many processes on the Earth. Although the sun emits a nearly constant amount of radiation (solar constant = 1361.1 W m-2), we experience considerable temporal and spatial variation in the solar radiation received on the Earth’s surface. Because of this, it becomes important to have a reasonably accurate knowledge on the availability and variability of GHI.

Why is accurate GHI Forecasting important for solar plants?

Today, solar irradiance forecasting receives unprecedented attention from various scientific communities. This is because of the importance of forecasting the variability of solar power for their grid integration, which constitutes a major challenge to a successful transformation of the conventional fossil fuel-based energy sector into a 100% renewable one.

Current challenges of GHI forecasting

It turns out, however, that current solutions lack localization of the forecasts. Additionally, such solutions do not also discuss the potential changes in GHI under the umbrella of climate change. But long-term radiation magnitudes recorded over different places proves that GHI undergoes substantial multi-decadal variations, which should be considered in solar resource assessments.

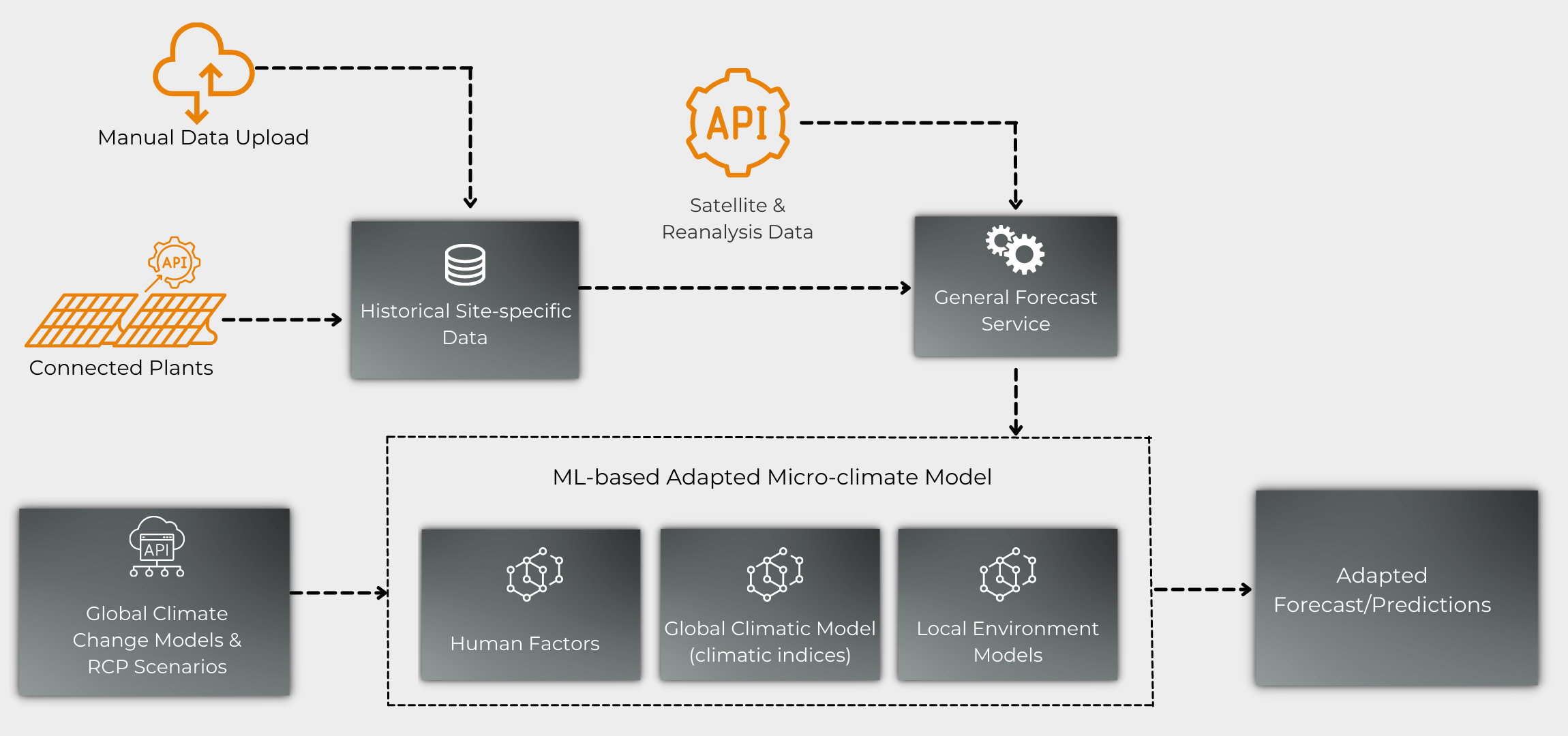

SmartHelio’s HelioCloud GHI Forecast service

SmartHelio’s HelioCloud GHI Forecast service predicts solar irradiation for any location in the world. To this end, it employs cutting-edge Machine Learning algorithms along with custom functions to generate insights from historical data that help reduce uncertainty in estimating global horizontal irradiance.

Furthermore, our algorithms take into account key influencing factors such as:

- The micro-climate of the location (surface roughness, NDVI, aerosol, etc.),

- Global climatic phenomena (ENSO, NAO, etc.),

- Climate Change (IPCC RCP Scenarios), and

- Human factors such as pollution, urbanisation, etc.

This helps us to achieve long-term forecasting accuracy up to 98%.

We believe that with HelioCloud GHI forecast, solar irradiation forecasting can be reinterpreted from a strenuous task into an effortless and user friendly process whose accuracy can be estimated with greater confidence.

To know more about our advanced GHI Forecasting tool you can book Ask Me Anything (AMA) session with our solar energy experts. Click on the button below to book your AMA session NOW!

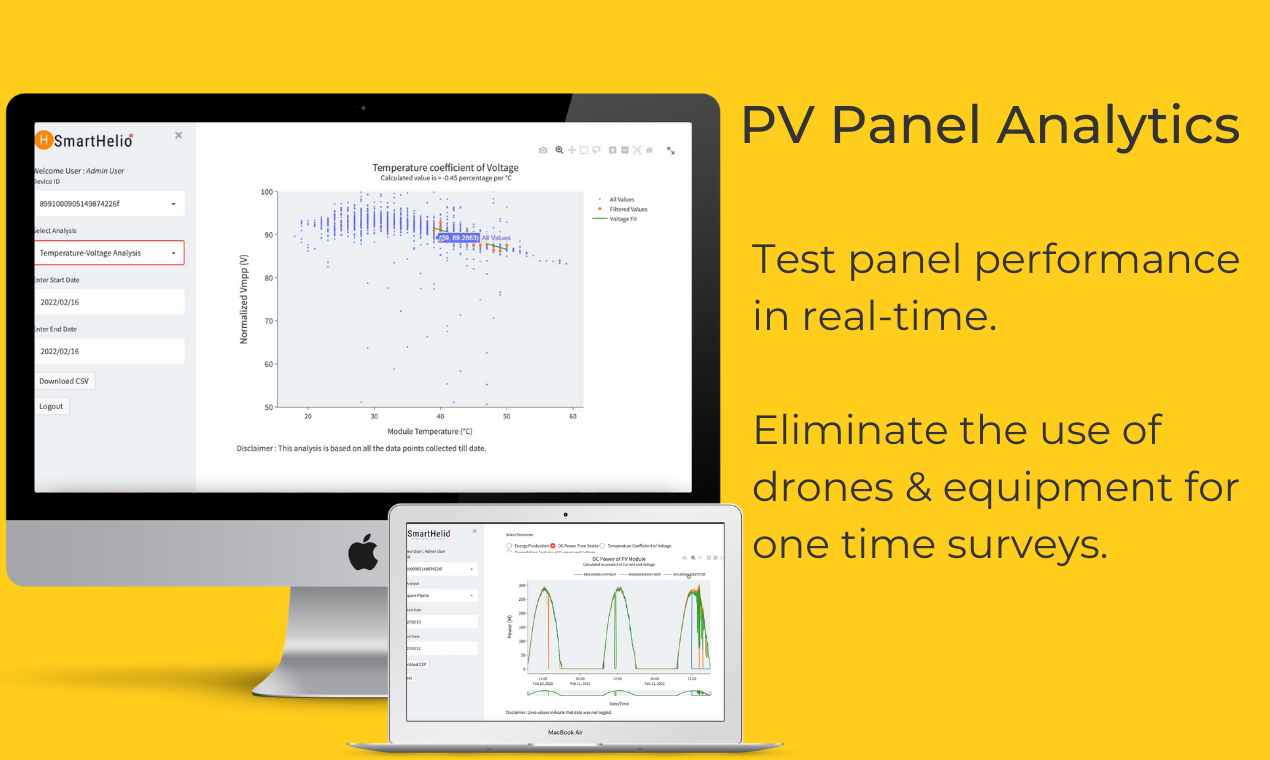

Your solar PV plants need panel-level analytics!

Enhance your inverter & string-level data insights for solar PV plant performance management with real-time panel-level analytics.

You might have seen data at a panel-level in real-time, but have you seen panel-level analytics in real-time?

As solar companies are expanding their portfolios, there is a pressing need for module-level data for better management of solar PV power plant systems. In such a scenario, only inverter-level data and string-level data is not sufficient for deep-data analytics. You need granular level data that can help you diagnose and predict faults in real-time. Our real-time panel level analytics eliminates the need for manual intervention and adds unforeseen value to drone and equipment surveys. Now companies can diagnose and predict the faults at the initial stage of module under-performance. Thus, saving money, time and energy.

Over the past 2 years, our panel-level analytics has helped global solar companies to identify and predict PID losses, module degradation, module mismatch, module tilt issues, cell cracks, and many more. Here are a few important use cases, based on our IoT device, that helped our client save more than 30% on O&M expenses and 8% higher energy production.

- Missing inverter data: Using AI and ML algorithms we predict missing inverter data with 99% accuracy.

- Pyranometer data accuracy: Validates the accuracy of pyranometer data.

- PV module degradation rate: Use our root cause analysis to identify, predict and compare faults like cell cracks, soiling pattern, wire losses, hot spots, connector faults etc.

- Compare different PV modules: Compare the performance of different module manufacturers and performance of the modules in different geographies.

“Our newly launched PV Panel analytics tool focuses on IoT technology and ML algorithms. We use this technology to provide module-level insights in real-time on any type of solar module. Companies can further enhance their R&D or analytics effort using our module-level raw data,” Sourabh Maladharee, IoT Head.

To know more about our PV Panel Analytics tool you can book Ask Me Anything (AMA) session with our solar energy experts. Click on the button below to book your AMA session NOW!

To know more about our PV Panel Analytics tool you can book Ask Me Anything (AMA) session with our solar energy experts. Click on the button below to book your AMA session NOW!