PLUG-IN SOFTWARE

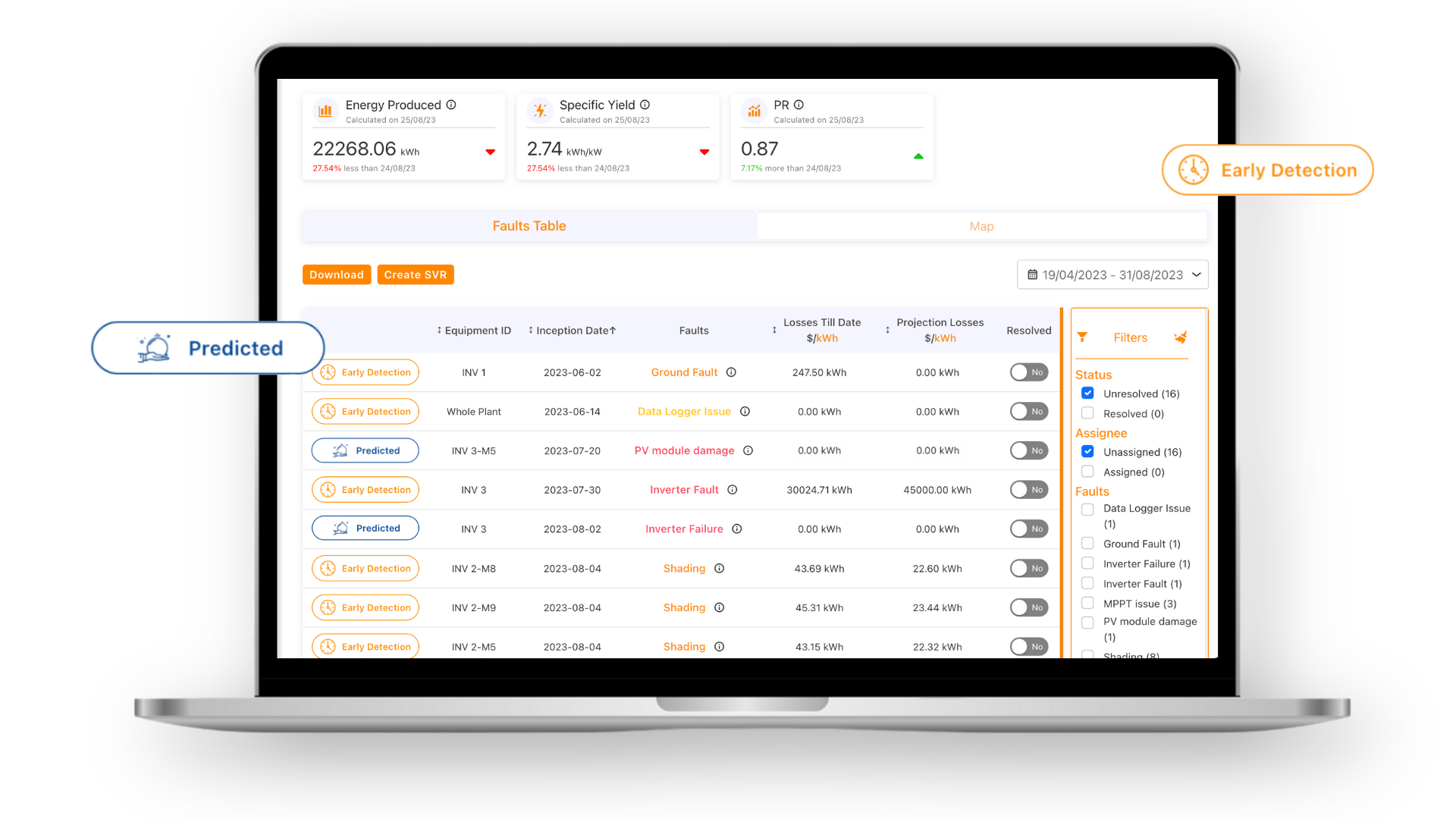

Get ahead of faults with Autopilot

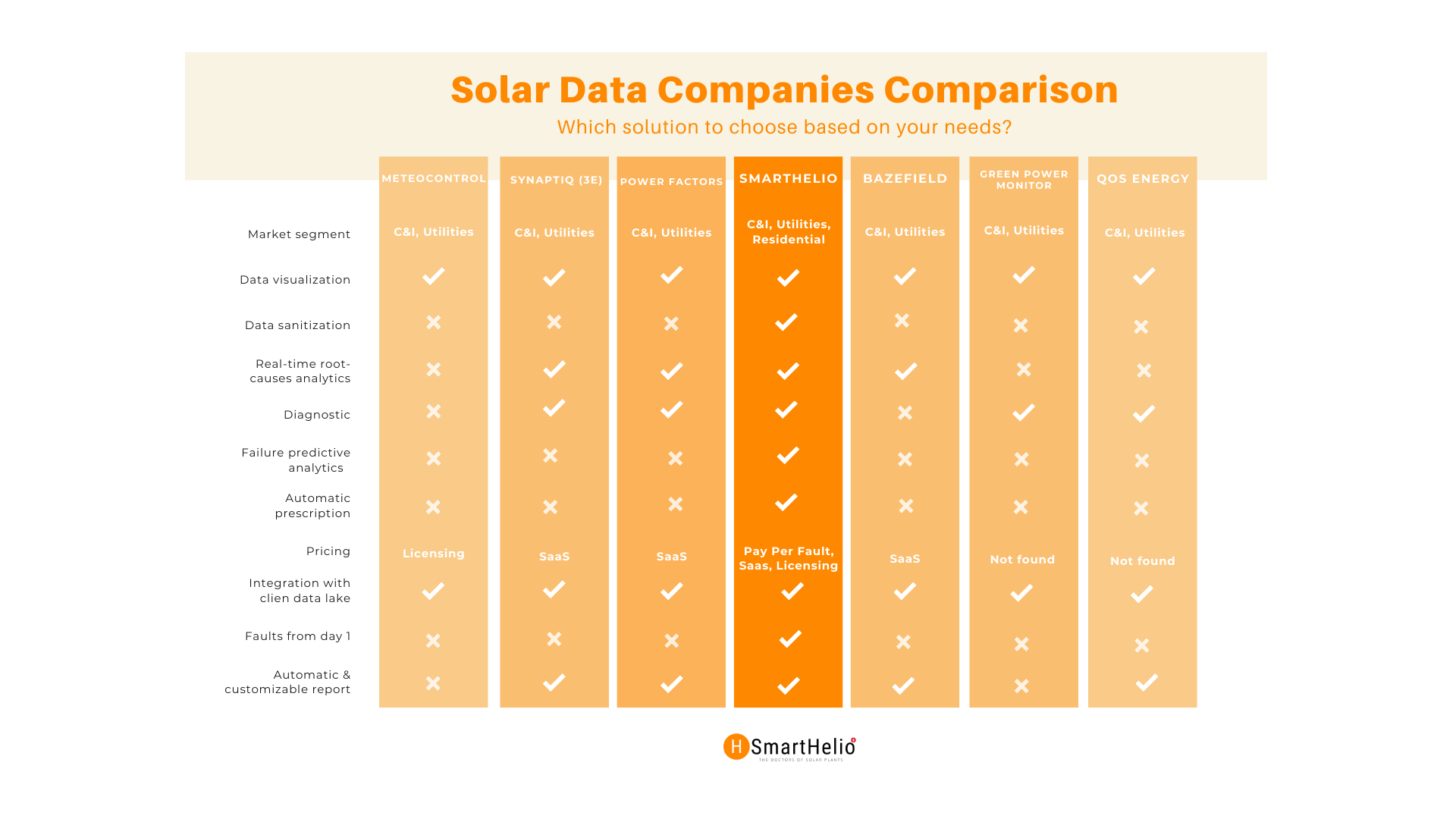

Our physics-informed AI algorithms detect and predict the unique signatures of 30+ various faults in real-time and before they happen with 95% accuracy. Integrate via API into existing SCADA or CMS platforms.

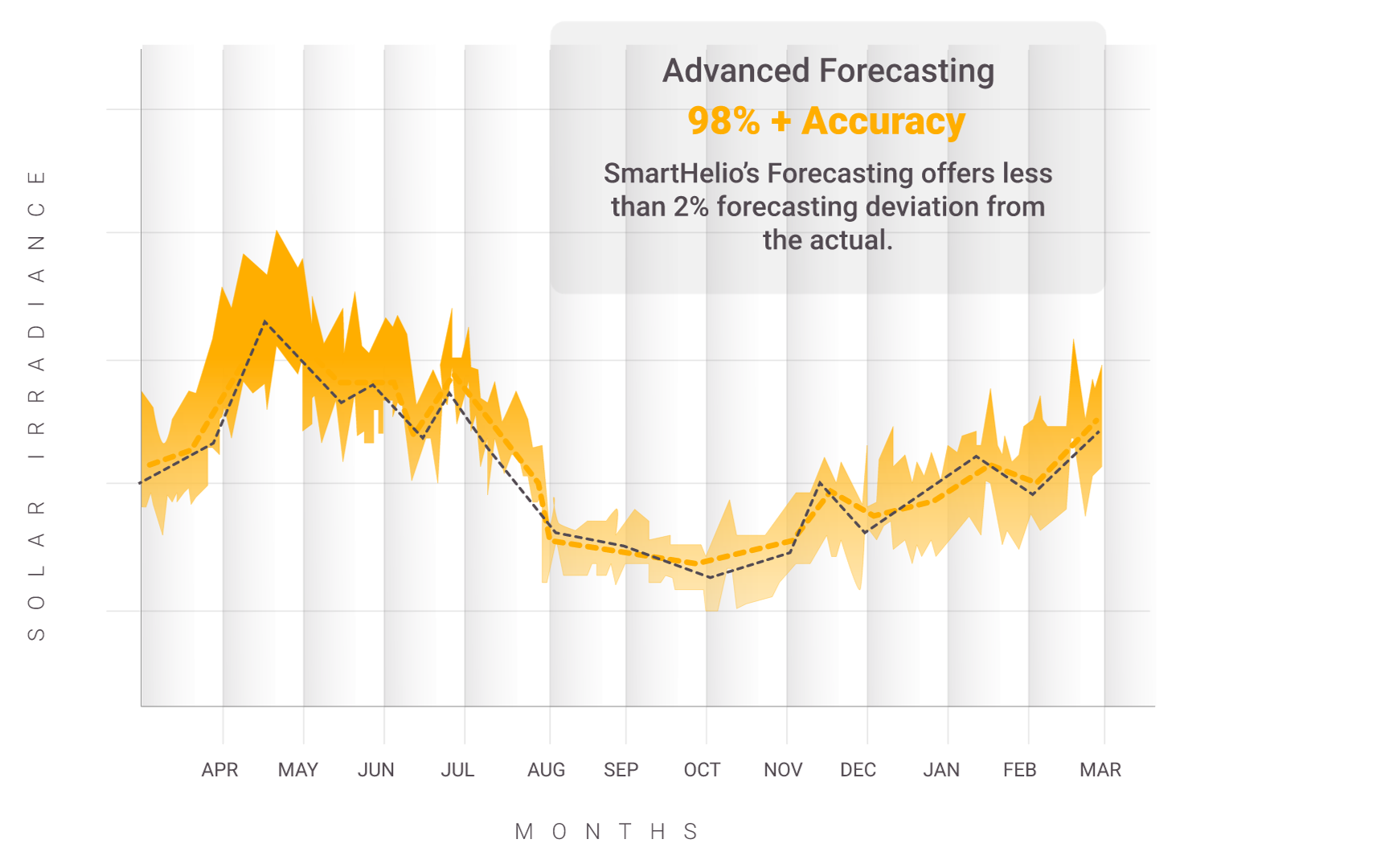

CLIMATE RISK ASSESSMENT

De-risk solar investments with climate forecasting

Based on climate change and over 100 variables, our Climate Risk Assessment forecasts long-term solar GHI and wind speed for solar developers, investors, IPPs, and banks.

“SmartHelio was quickly identified as the best fit for us […] They identified all the errors that we also found with our current monitoring solution. Plus, they also could identify some more failures which we didn’t know about yet.”

David Ebner, Project Engineer

“An increase in PV power generated by the panel is one value. There was a series of ground faults, which may cause over-voltage and even fire risk […] Safety is a number one priority for Schneider. We see the safety improvement as a second value to SmartHelio’s technology”

Luc Hossenlopp, CTO Digitalisation

By the Numbers: Our Energy Impact

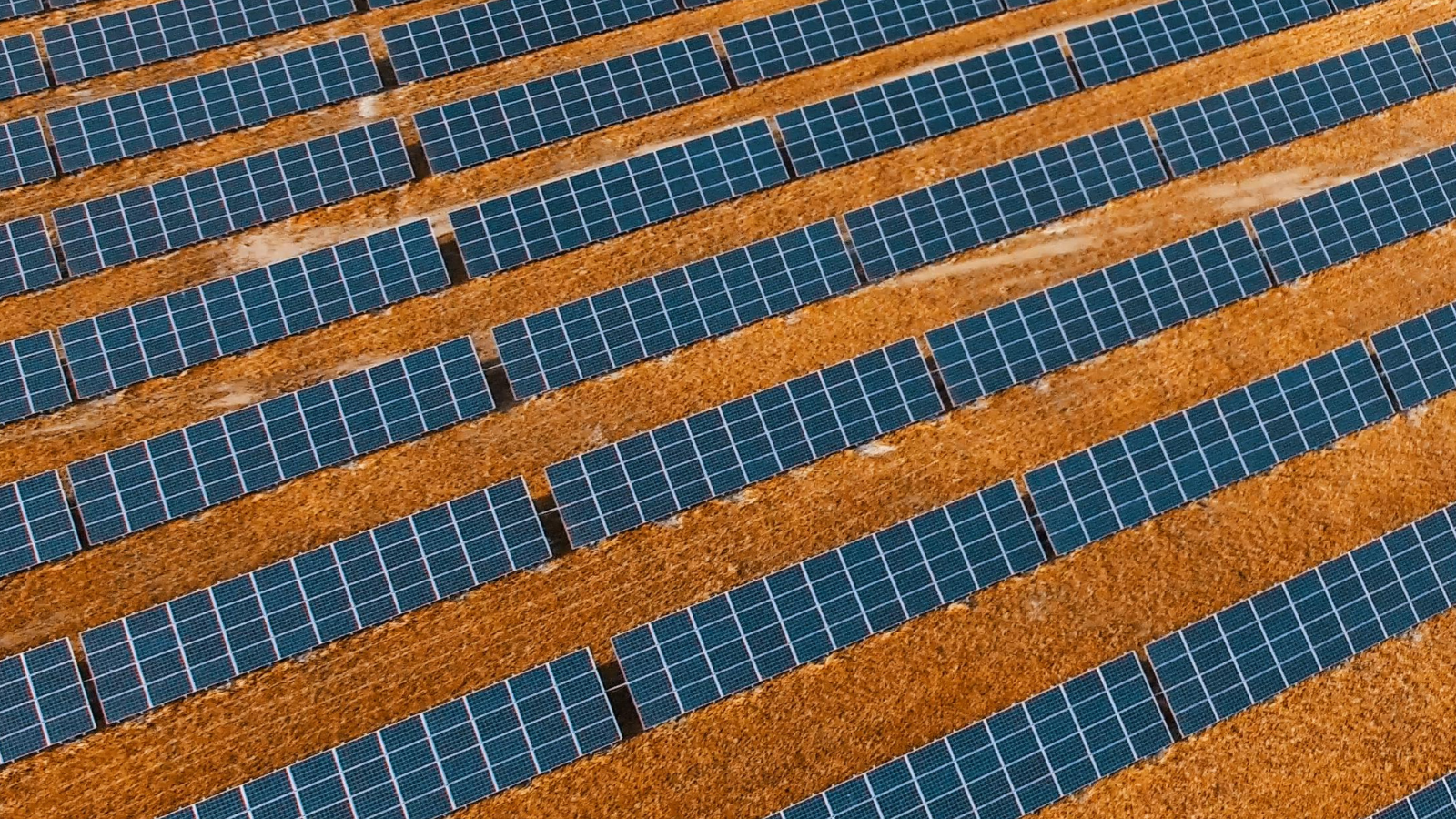

5GW

Assets Under Management

$25M

Invested in R&D

5B+

Labelled Data Points Analyzed